FILLING MACHINE: MAKING AN ADDITIONAL PRODUCT ON AN EXISTING PRODUCTION LINE

Challenge

To answer the question: get a new filling machine or adapt an existing one?

This food company’s factory in Rotselaar, which specialises in dairy and plant-based products, wanted to expand its product range with a plant-based product. This would make it a hybrid production site. Vegetable products would be produced in addition to dairy products.

But there was not enough production space on their site for the expansion.

The key to success therefore lay in adapting the filling machine they already had. However, the manufacturer for that production line declined the assignment, arguing that it was too complex. Instead, they proposed building a second, additional line.

The food company contacted us to see if something could be done with their existing filling machine. Could this existing line be modified to handle a second product without the risk of cross-contamination between the vegetable product and the dairy product?

Solution

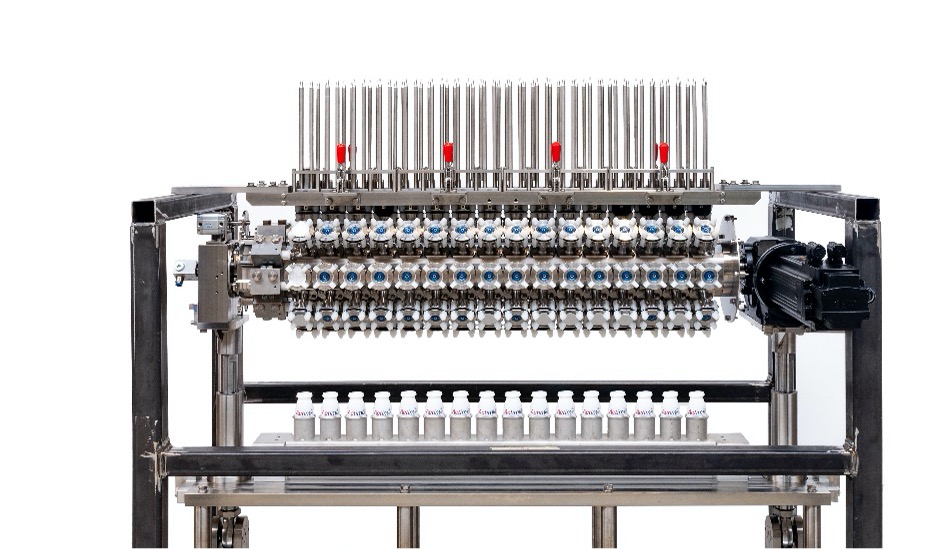

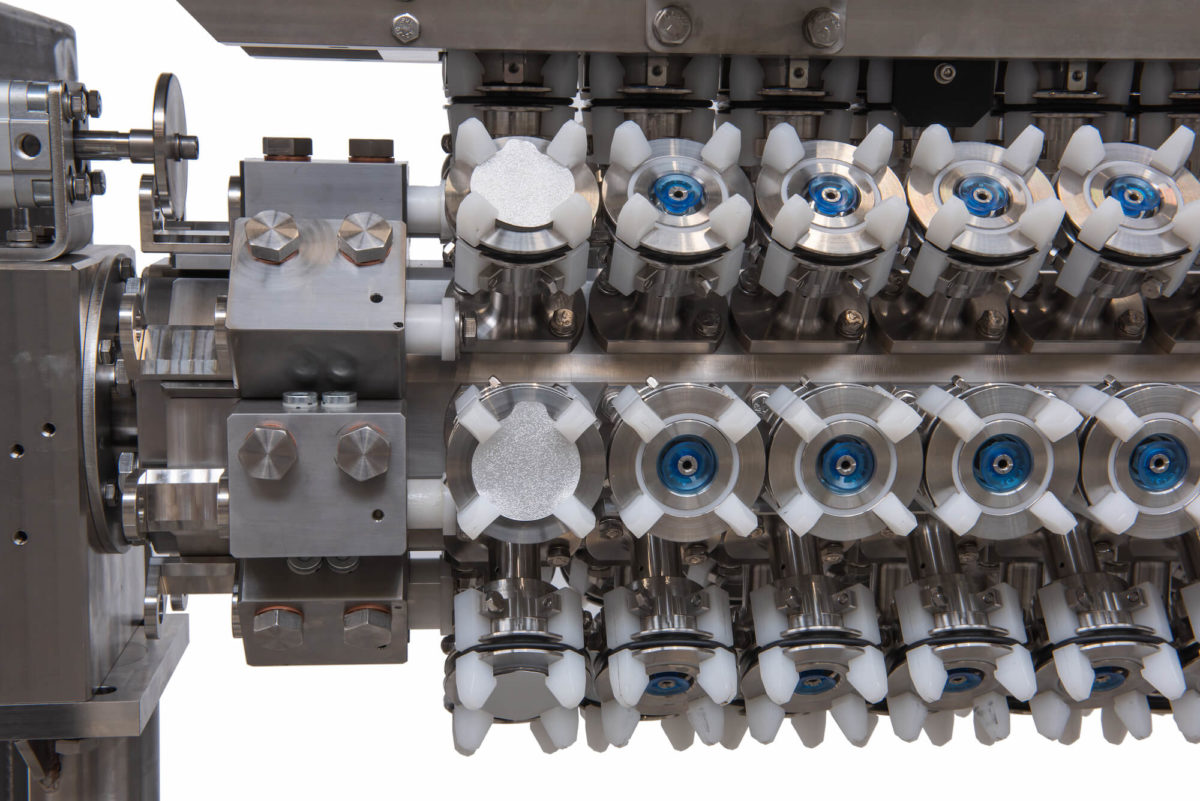

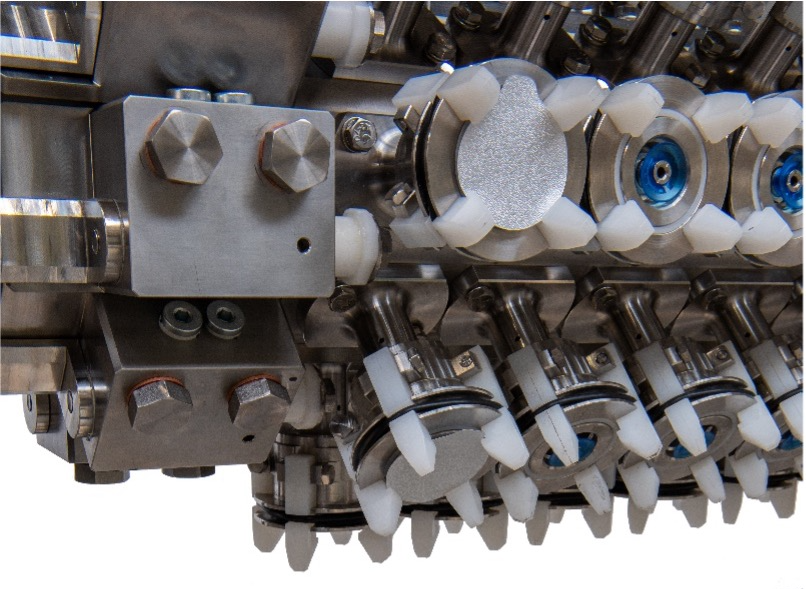

We built a new heart for their existing filling machine: a multifunctional filling carousel that combines all the earlier, sequential steps:

- Centring

- Filling

- Bottle straightening

- Sealing with an aluminium lid

- And, finally, putting a cap on.

Results

- An additional filling installation integrated into an existing machine.

- Making two products instead of one on the same floor area and with the same machine.

- A solution for a fraction of the investment needed for a new production line.

- Realisation in a much shorter lead time than a new machine.

- A faster and more precise filling process. This was done by combining what used to be separate process steps.

- A more energy-efficient filling machine. The old drive was replaced by a servo-controlled one.