Design. We translate your business case into a machine that creates new possibilities. With great attention to hygienic design, of course.

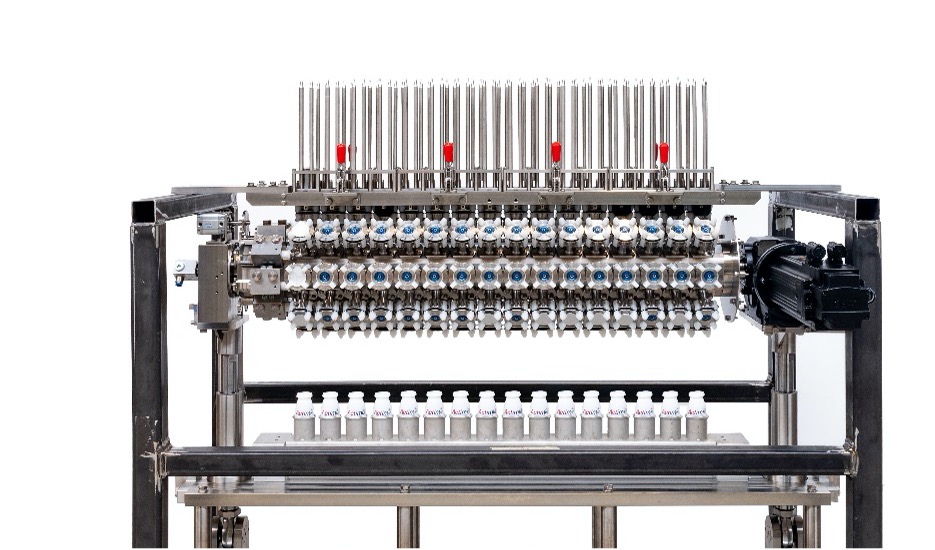

Custom machines for the food industry

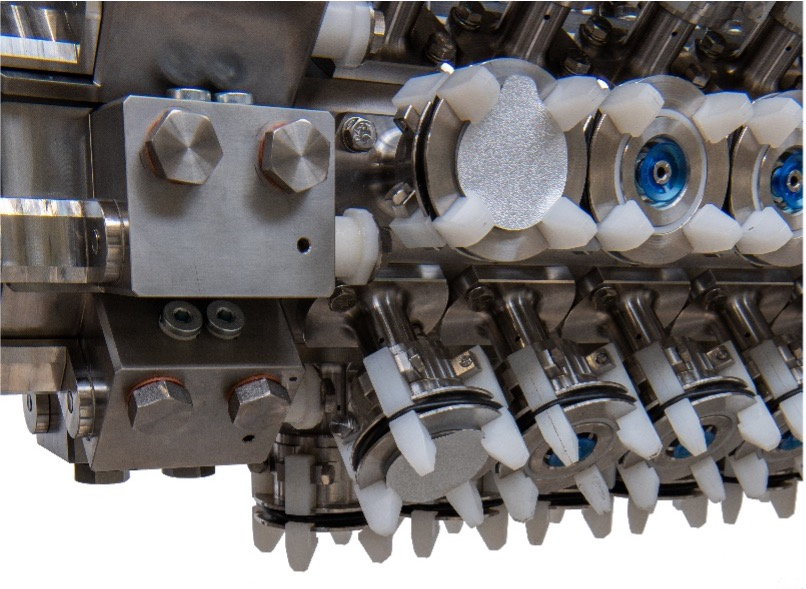

You are looking for solutions to deal with increasingly stringent regulations. Cleanability and a high level of finish are a must.

But what if a custom machine was also the answer to the tight labour market? Clear interfaces. Self-steering, operator independent, with simplified maintenance. So that your machine becomes accessible to a wider public.

With a customised machine or a retrofit of an existing machine, we help you meet those challenges.

What we do for you

Invent

Manufacture

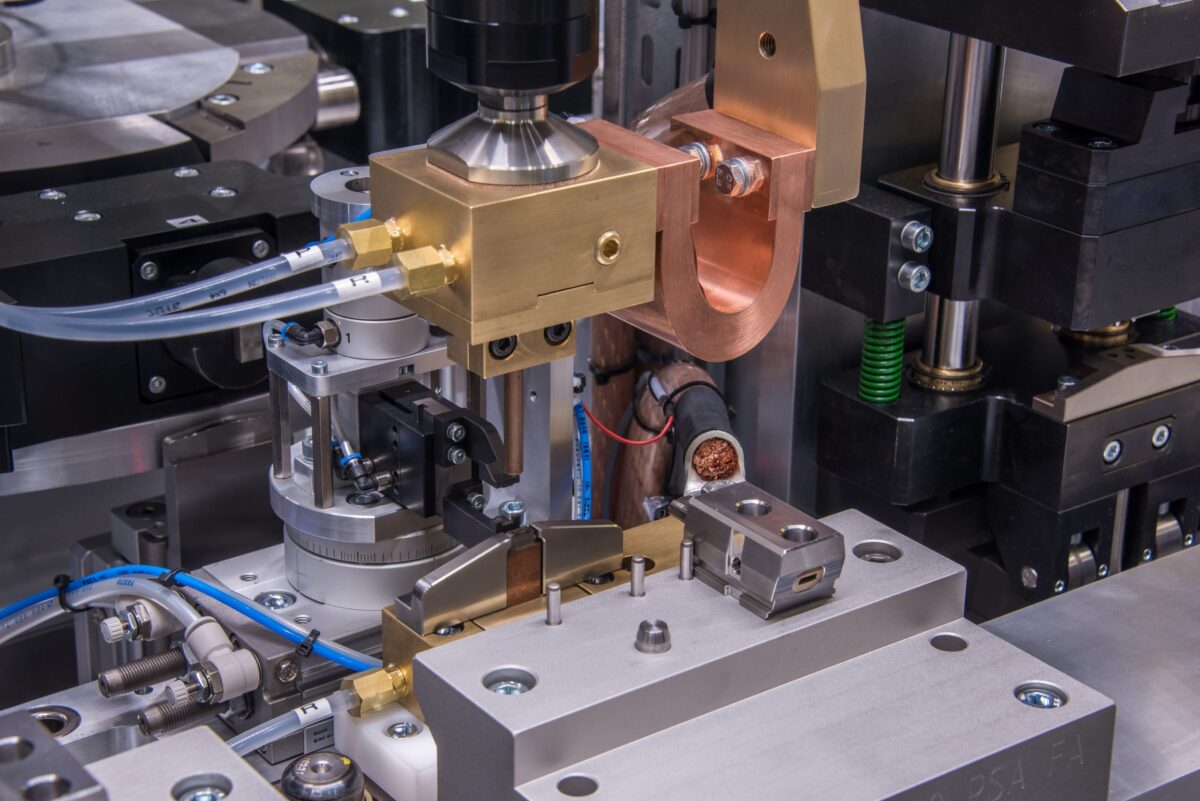

From design to assembly. We keep every step of the construction of your machine in-house to ensure the highest level of finish. For example, we have a separate welding workshop especially for stainless steel constructions.

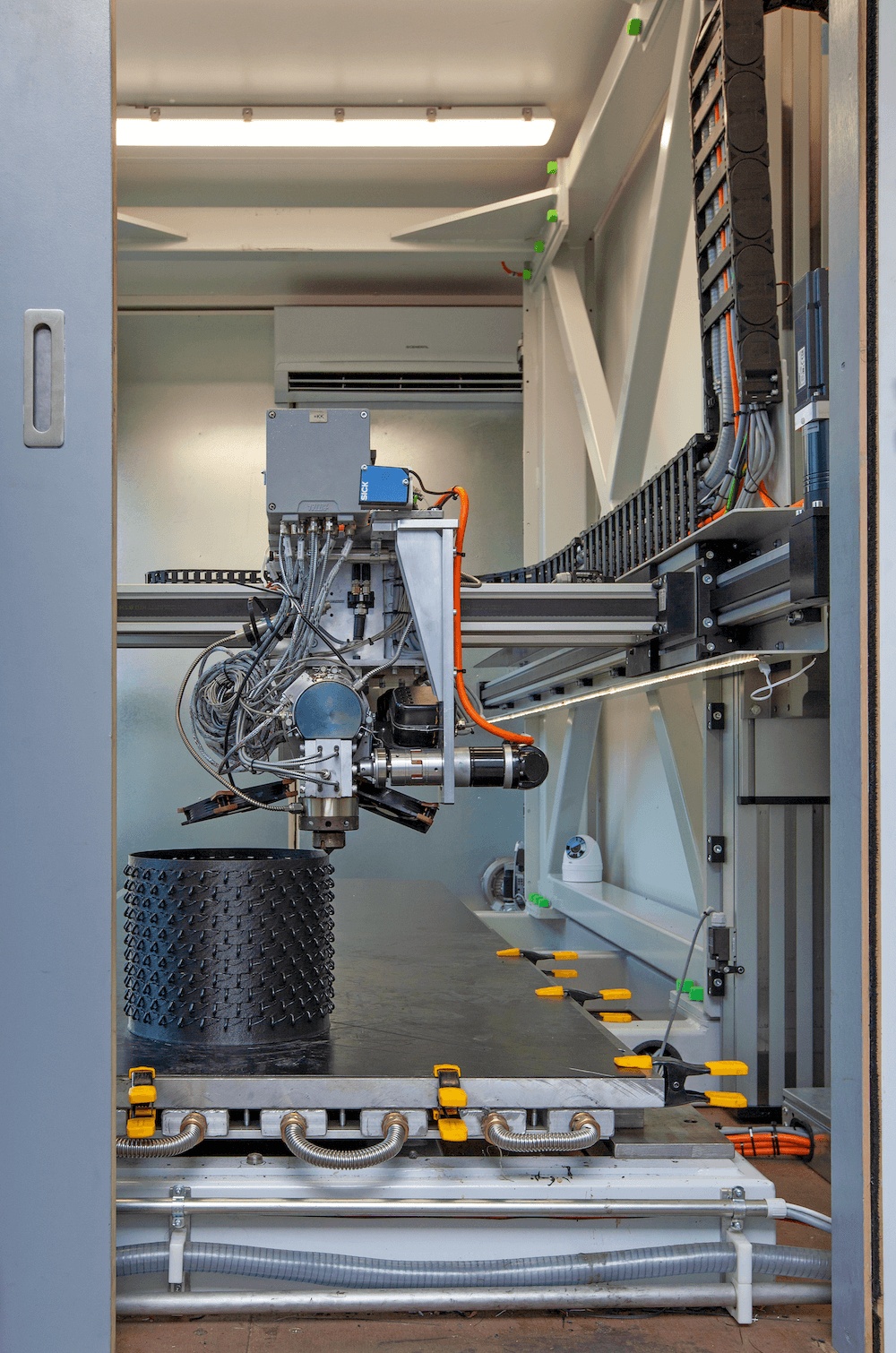

Retrofit

Conversion. Is your machine still mechanically sound? And do you want to incorporate a second filling line or certain innovation into that existing installation, for example? We help you take several steps forward: software-wise and mechanically, electrically and digitally.

Whitepaper: machine upgrading