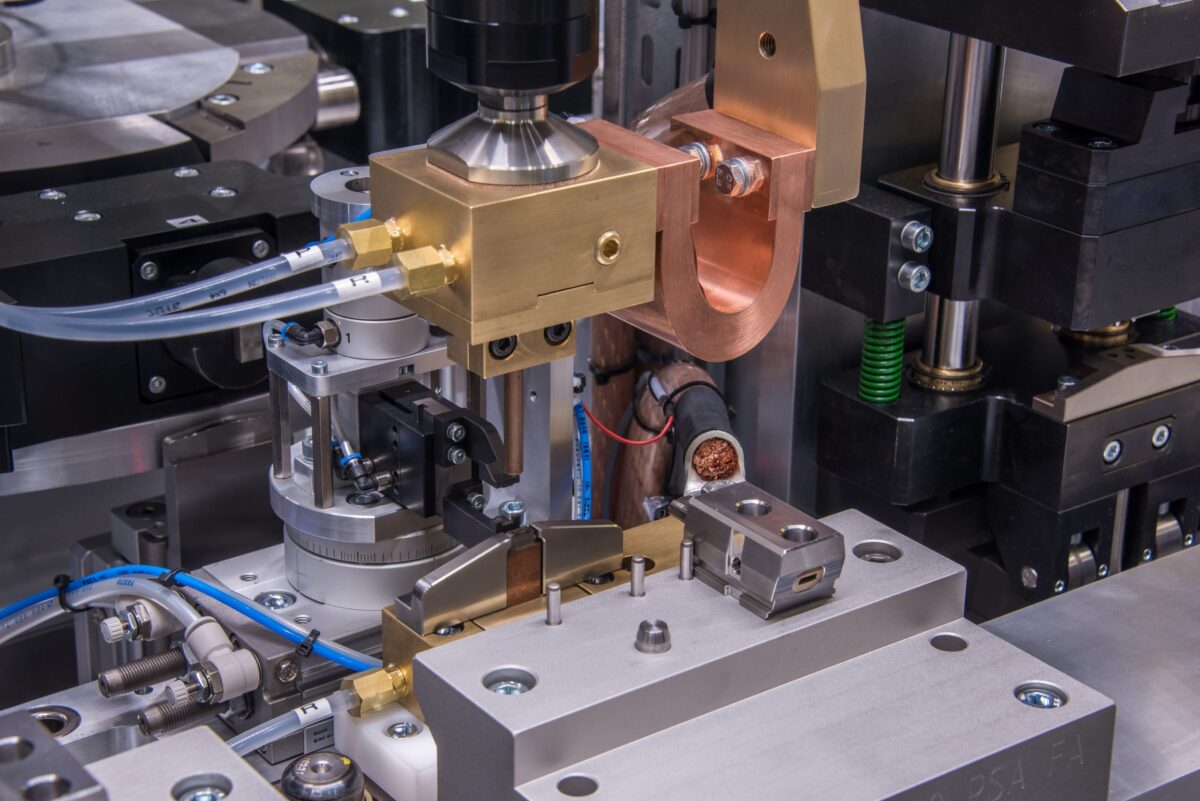

Design. We draw up a robust design. A sturdy machine with great attention to maintenance and safety.

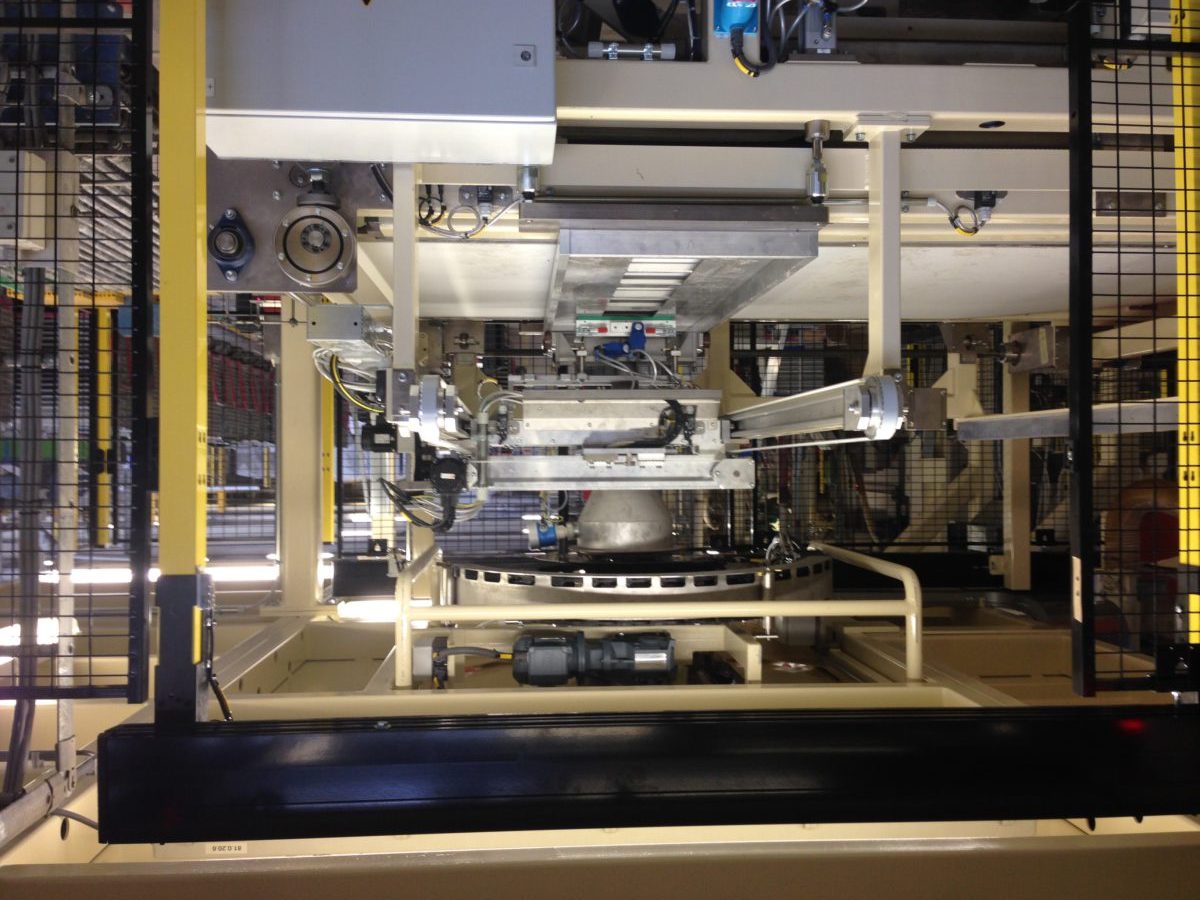

Custom machines for the construction industry

Better safety for your employees. Easy to maintain. Secure the knowledge of your operators or craftsmen.

At the same time, you want a robust machine you can rely on even in the most demanding conditions: dust, vibrations, humidity …

A custom machine provides an answer to all those challenges. We design and assemble a custom machine that takes all these aspects into account. In doing so, we always weigh up the business economics, because your investment must obviously pay off.

What we do for you

Invent

Manufacture

From design to assembly. We keep every step of building your machine in-house. So we guarantee quality and the fastest possible delivery time.

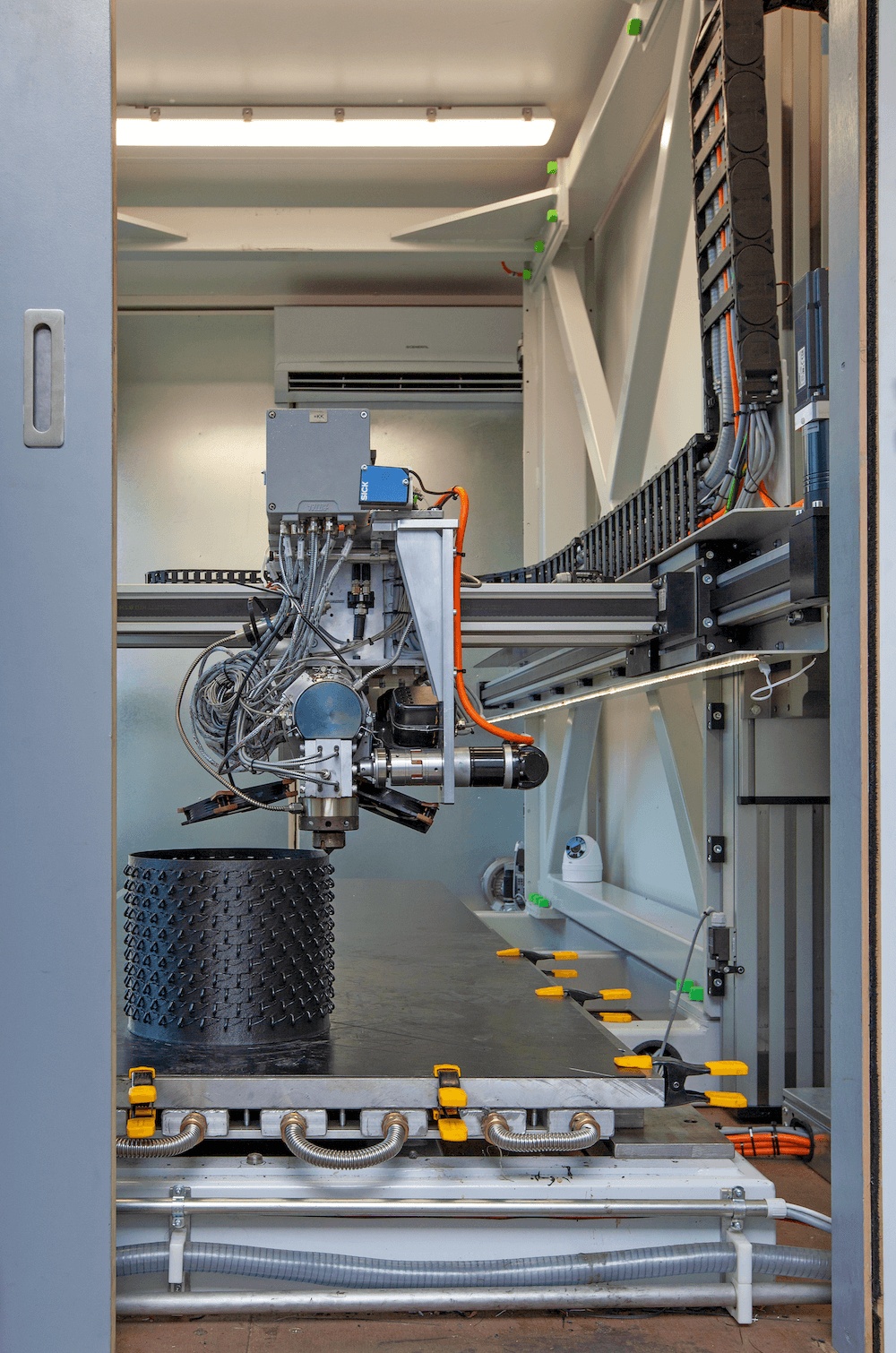

Retrofit

Conversion. Is your machine still mechanically sound, but has a safety issue? Or do you want to make them more energy-efficient and user-friendly? We help you take several steps forward: software-wise and mechanically, electrically and digitally.

Whitepaper: machine upgrading