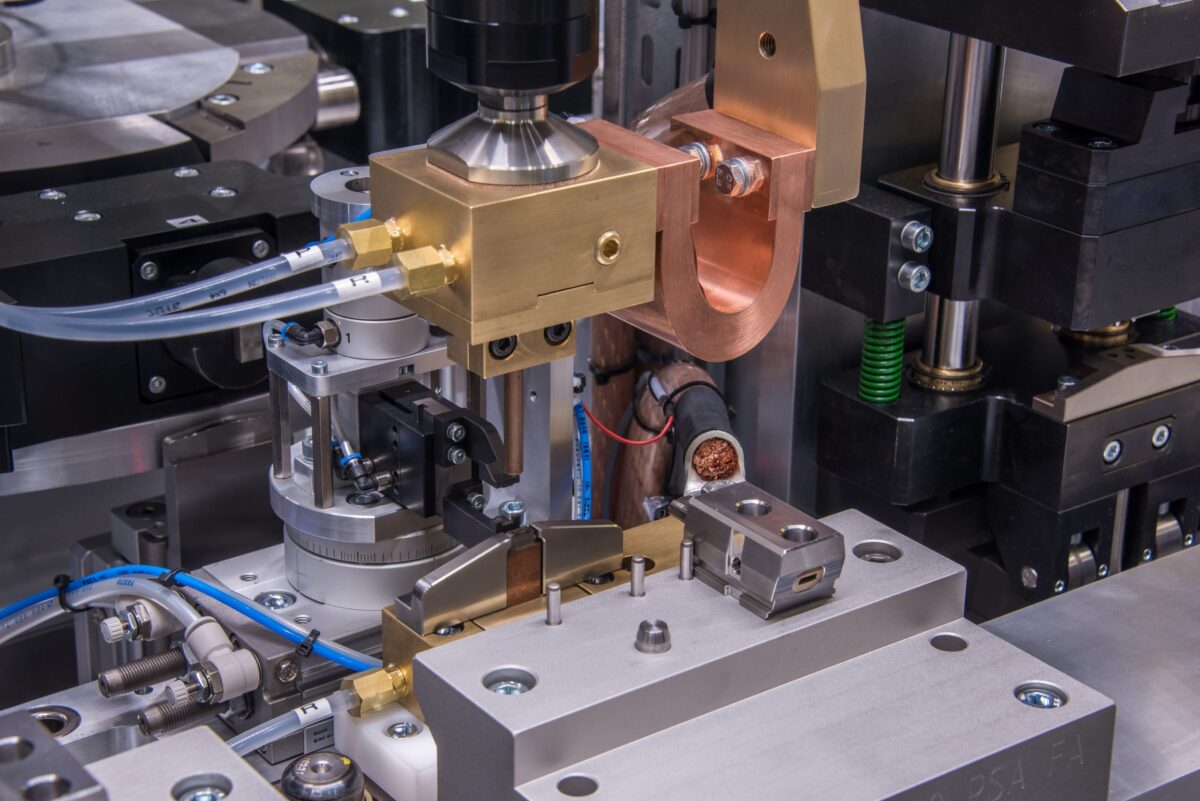

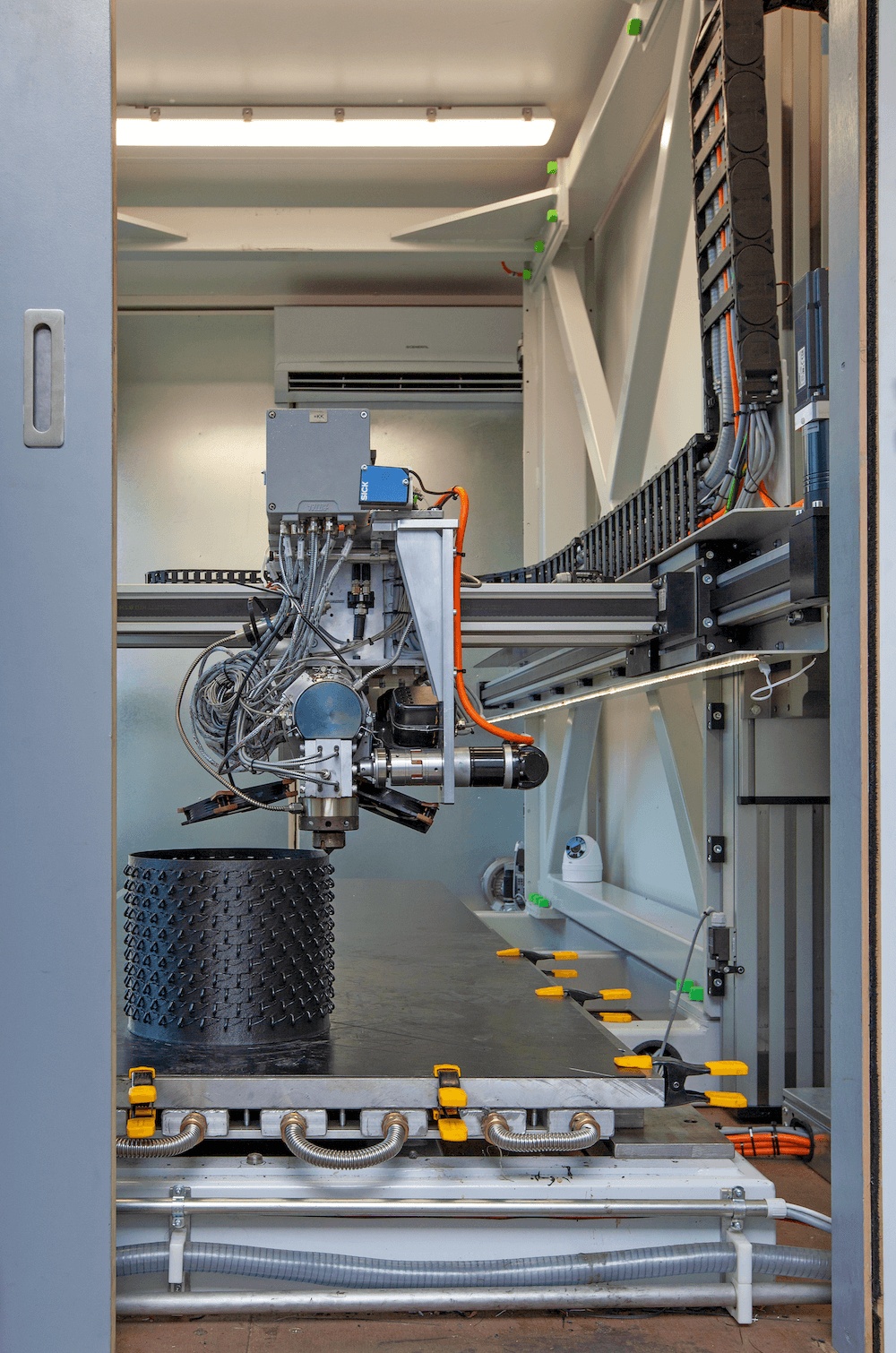

Design. We translate new technologies into new possibilities for your processes. To produce faster and more precisely or to further automate and digitalise your processes.

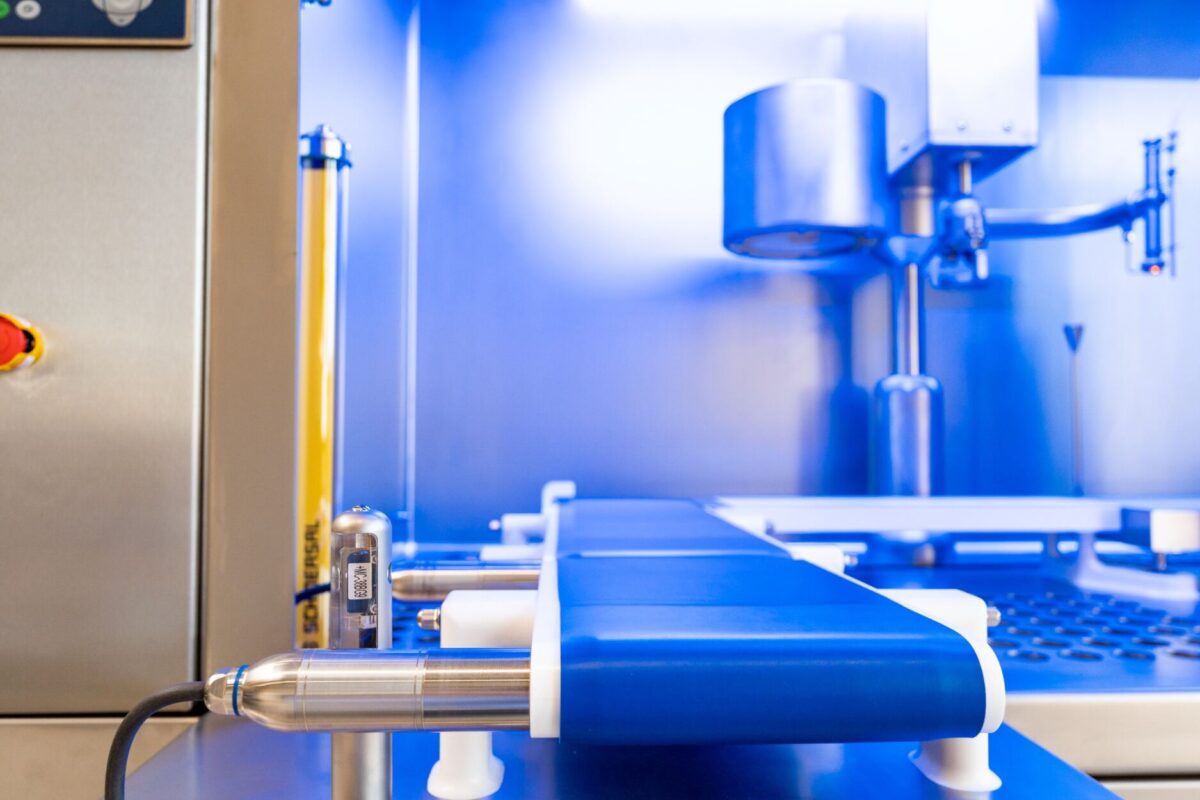

Custom machine development for the pharmaceutical industry

Efficiency, quality and safety. In the fast-moving and changing landscape of the pharmaceutical industry, these are three top priorities.

To meet these challenges and meet the increasing demand for innovative medicines, you are always looking for the new possibilities of advanced technology. In order to further develop the way you produce, test and package.

A customised machine helps you strengthen your market position and secure knowledge within your company.

What we do for you

Invent

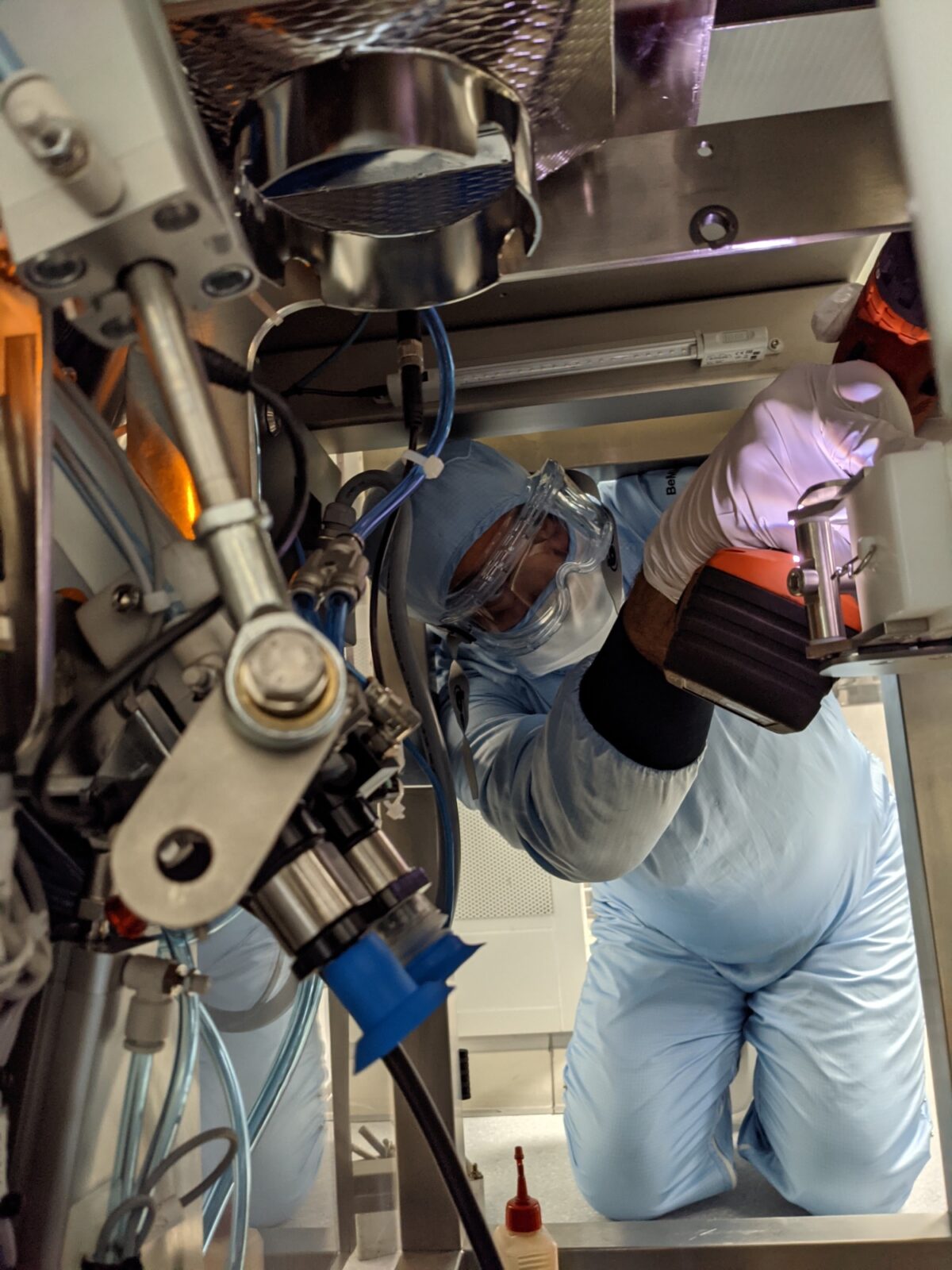

Manufacture

From design to assembly. We keep every step of building your machine in-house. So you get a result of the highest quality.

Retrofit

Renovation. Is your machine still mechanically sound, but the control system is absolete? Or do you want to incorporate an innovation in an existing installation? We help you take several steps forward: software-wise and mechanically, electrically and digitally.

Magazine : The future of

Pharmaceutical Manufacturing

Accelerating innovation in life sciences