We translate new technologies into new possibilities for your processes. To produce faster and more precisely or to further automate and digitise.

Automotive

Custom machine development for the automotive industry.

Shorter lead times, quick switching between product types and high reliability of your machinery.

A tailor-made machine will help further develop your processes and improve your uptime. So that you find an answer to the challenges you face.

We translate your business case into a custom machine that makes perfect technical and business sense and helps improve your OEE.

What we do for you.

Invent

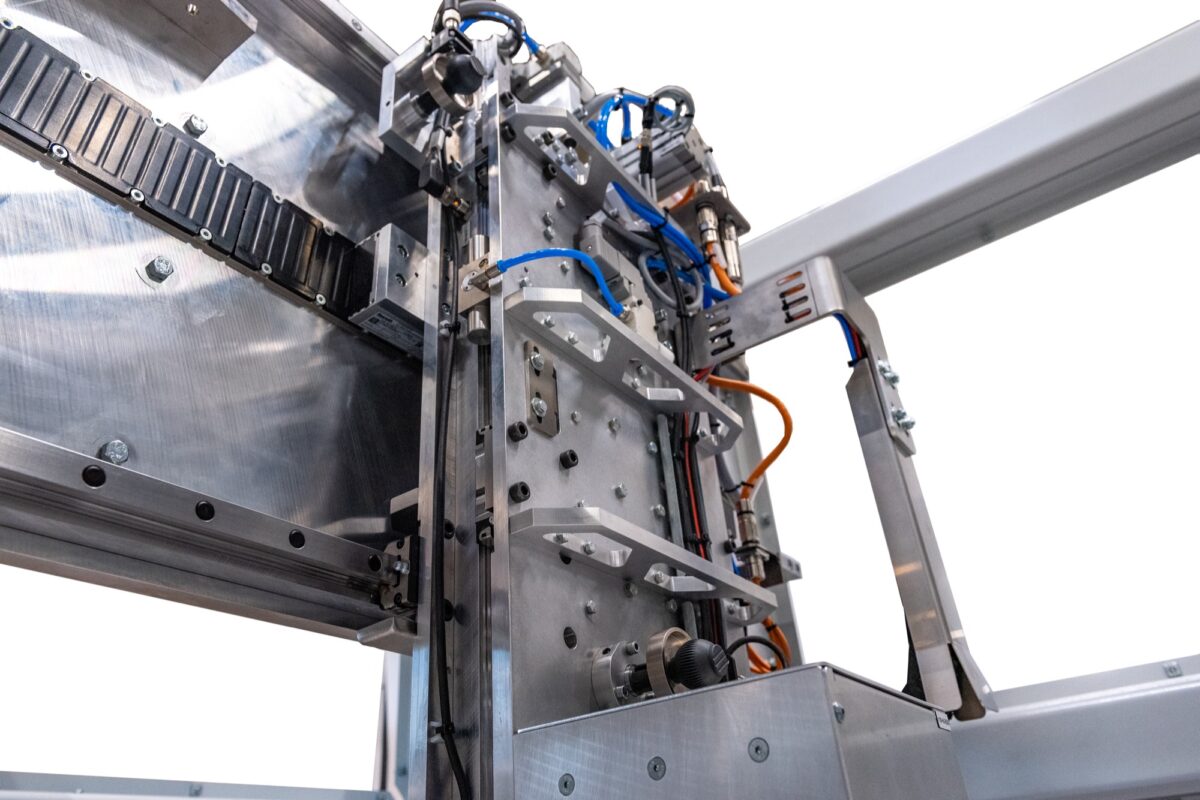

Manufacture

From design to assembly. We keep every step of building your machine in-house. So you get a finish of the highest quality.

Retrofit

Conversion. Is your machine still mechanically sound? Or do you want to incorporate an innovation in an existing installation? We help you take several steps forward: software-wise and mechanically, electrically and digitally.

Whitepaper: machine upgrading

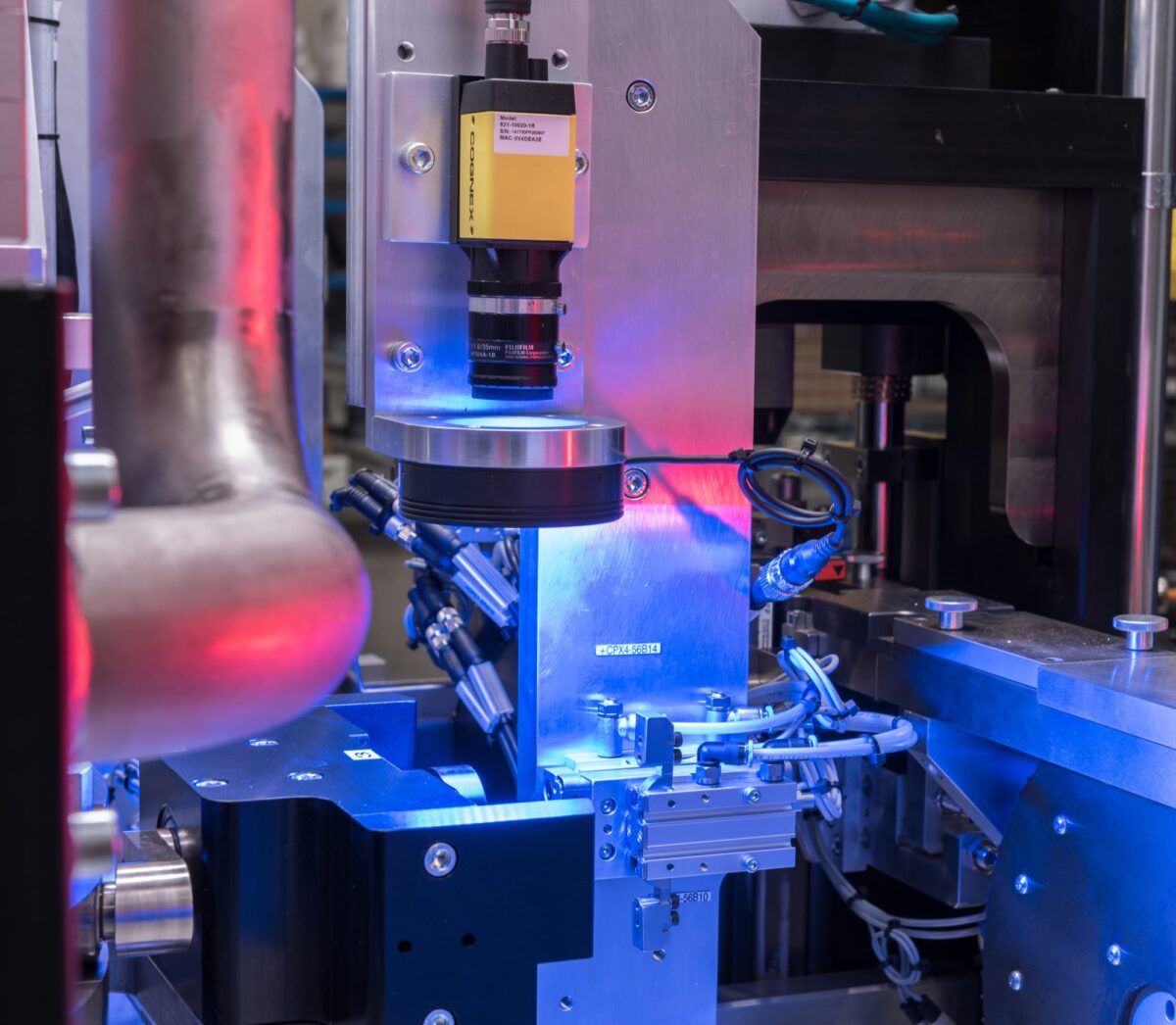

Vision Systems

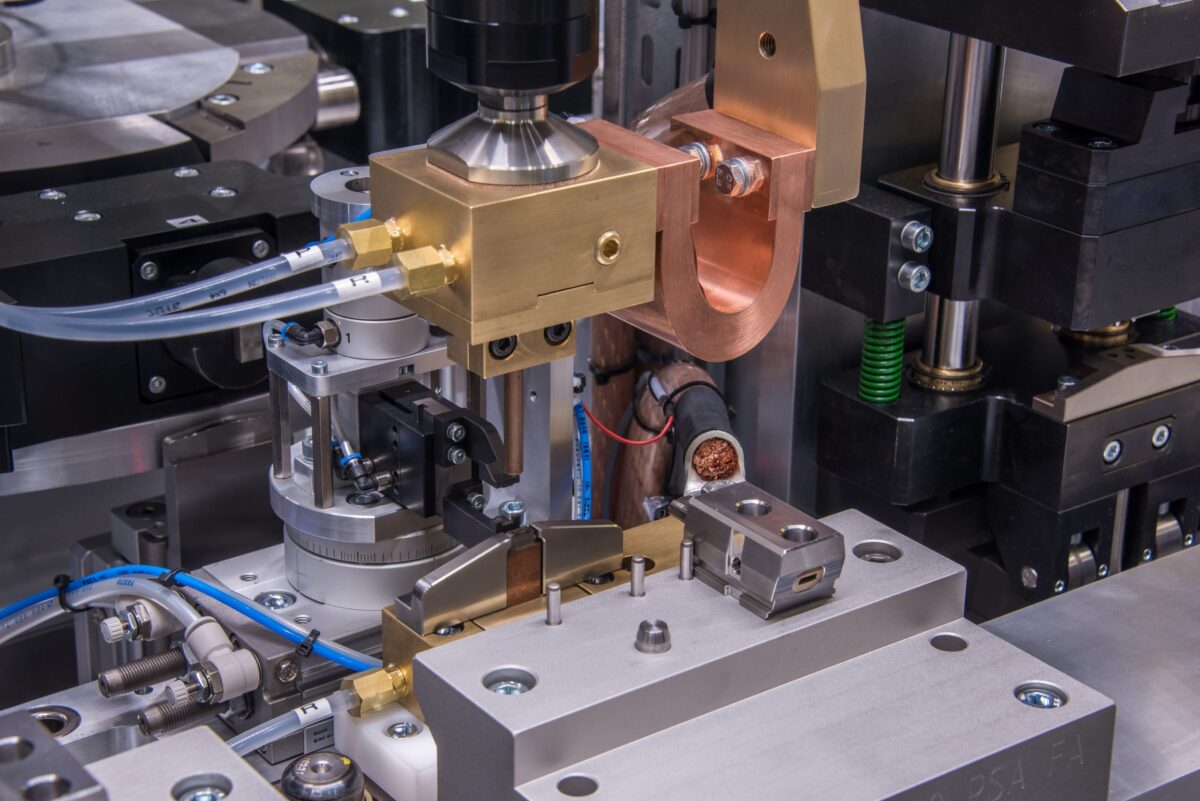

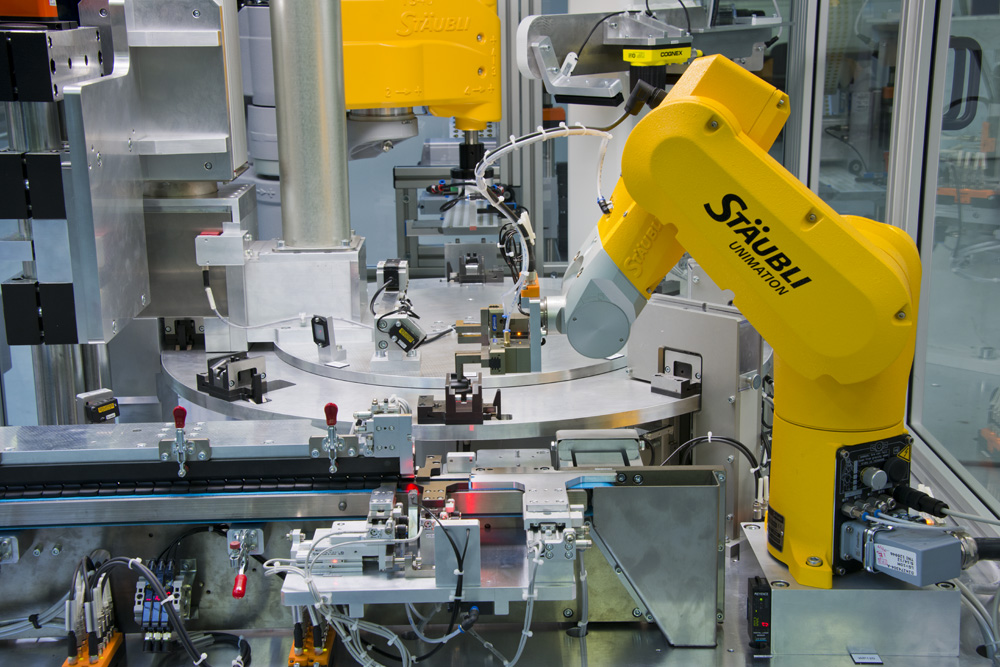

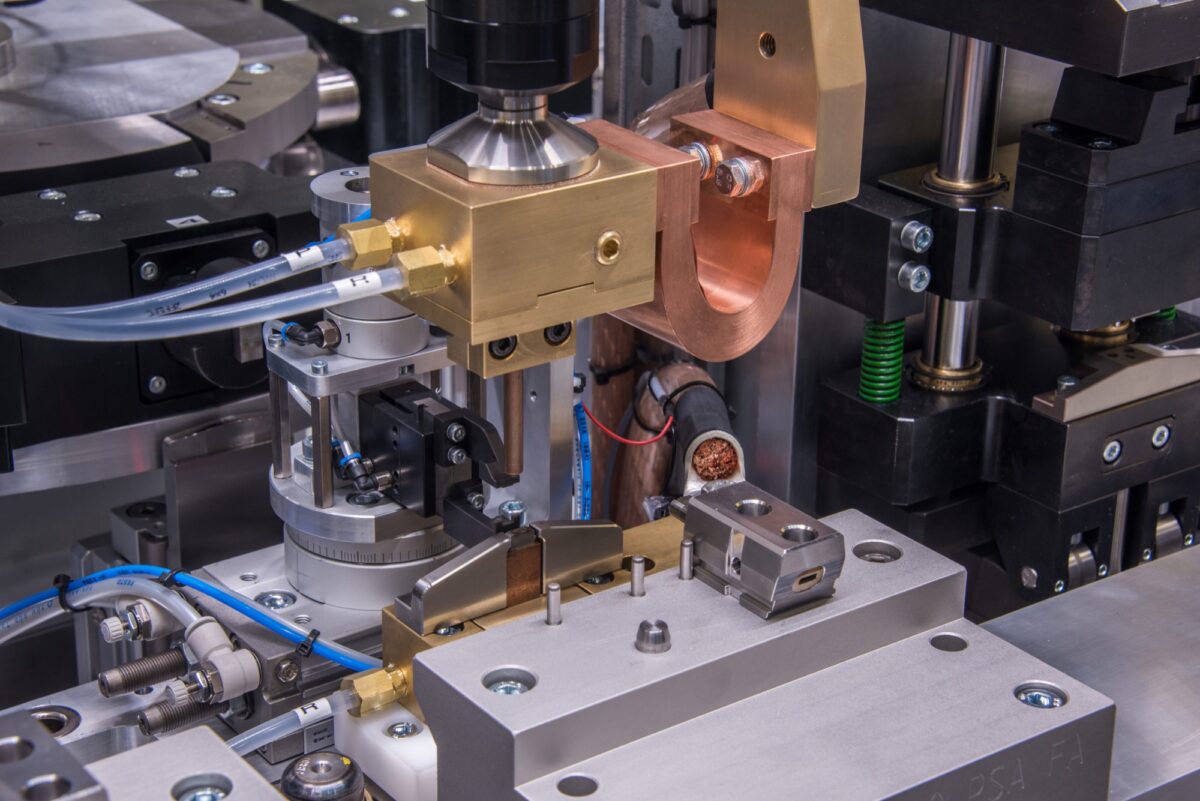

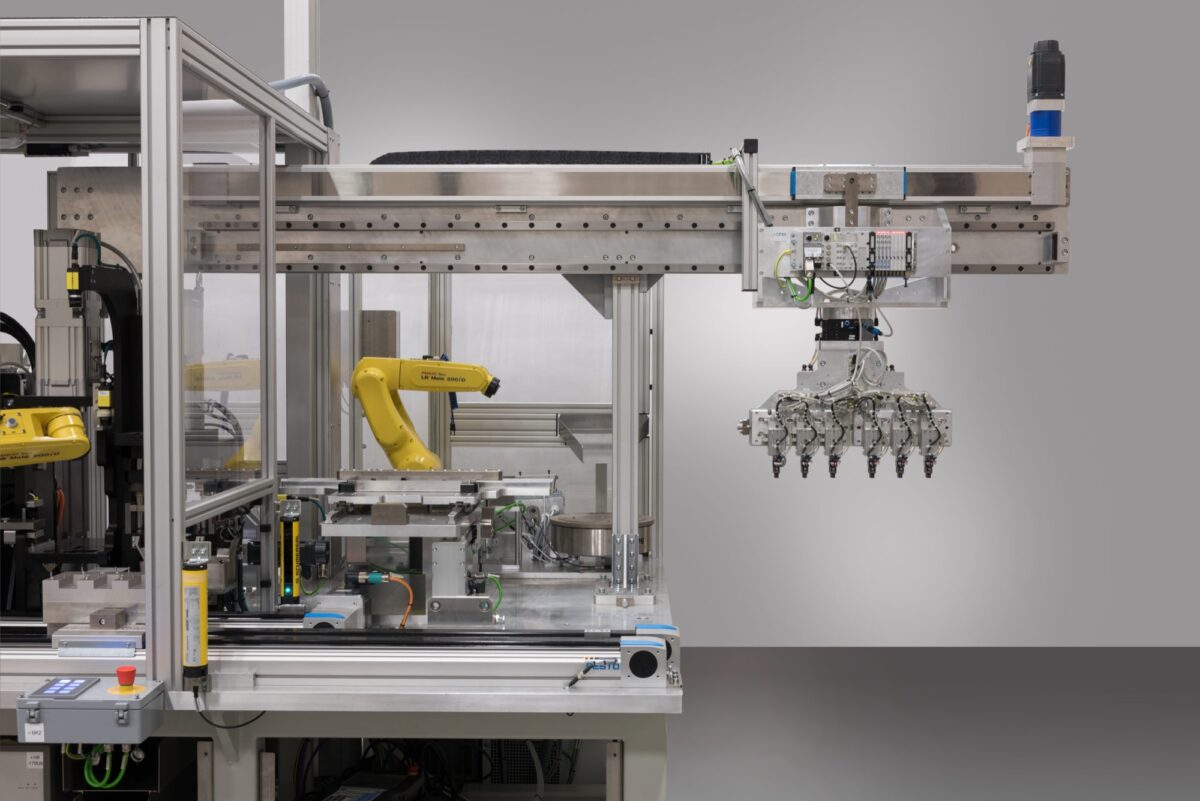

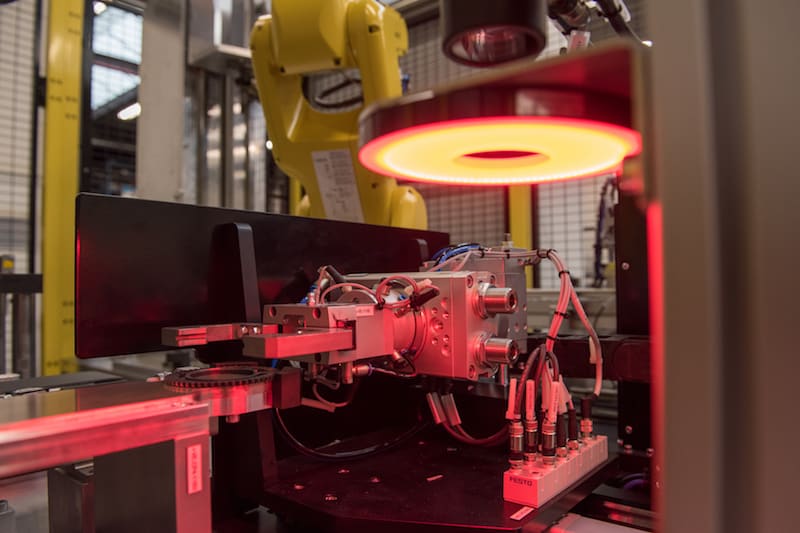

turntable automation

handling & assembly

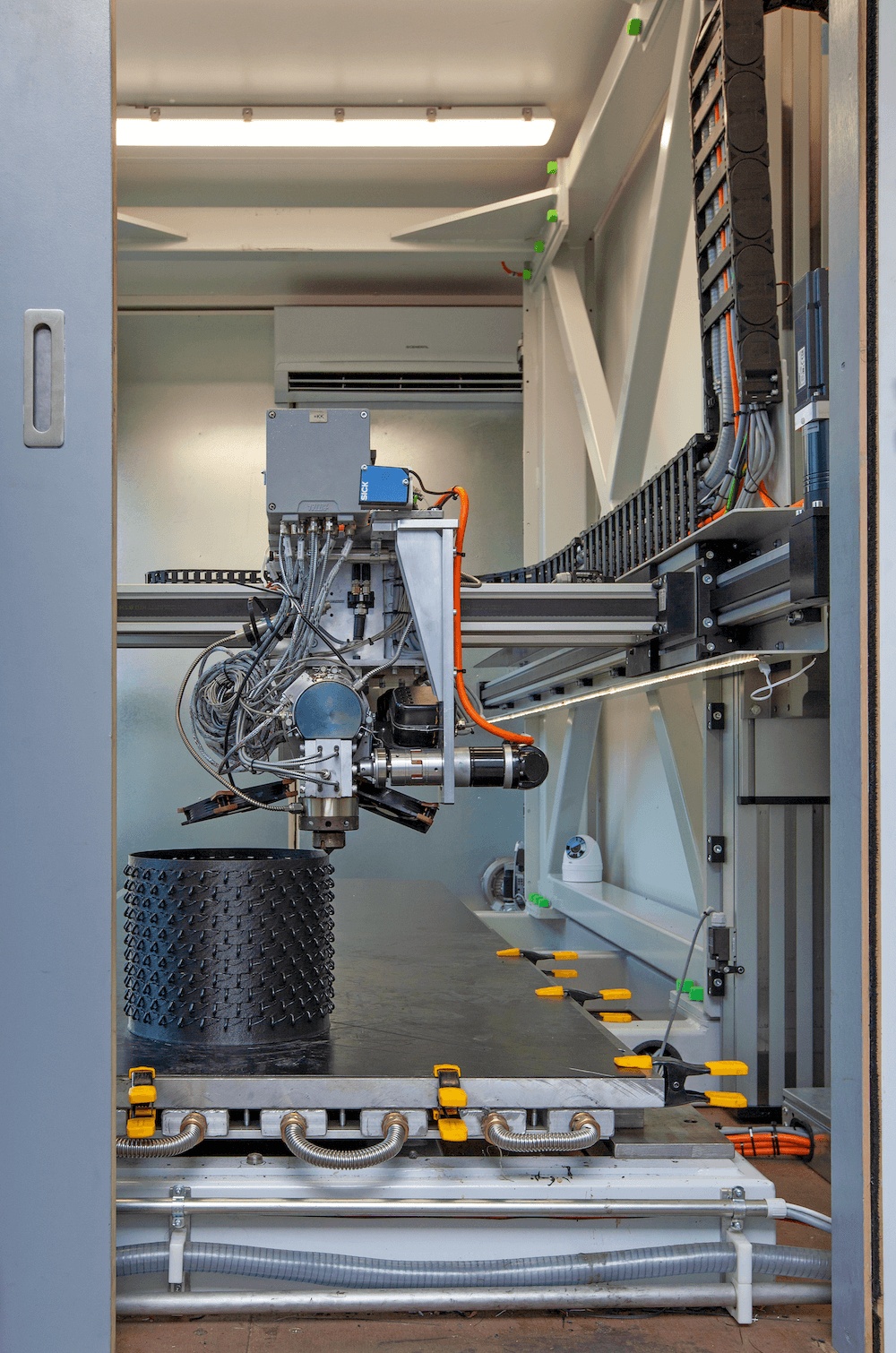

feeder systems

advanced motions systems

Our strengths for the automotive sector:

For more than 35 years, we have been building machines for automotive companies and suppliers. Our strengths:

The process

Step

Analysis

Analysis of your demand from a technical and business point of view. Until one winning concept remains.Step

Design

Converting that concept into a mechanical and electrical design.Step

Assemble

Those designs form the basis for components, assembly and cabling.Step

Program

We write the software for control systems: PLCs, HMIs, drives, robots and vision systems.Step

Build

After all tests in our workshop, we install the machine at your premises. Including tech transfer and training.Contact us

Trust us with your next project.

Contact