Design. We translate new technologies into new possibilities for your processes. To produce faster and more precisely or to further automate and digitise.

All-round machine developer

Our strength is that we are an all-round machine developer. We design, build and retrofit customised machines. And we do this for companies in wide variety of sectors – from SMEs to the lead plants of multinationals.

We have the right answer for every stage of your machine’s life cycle. Because if you want to move forward as a company and innovation is key, we will help strengthen your market position with a customised machine.

What we do for you

Invent

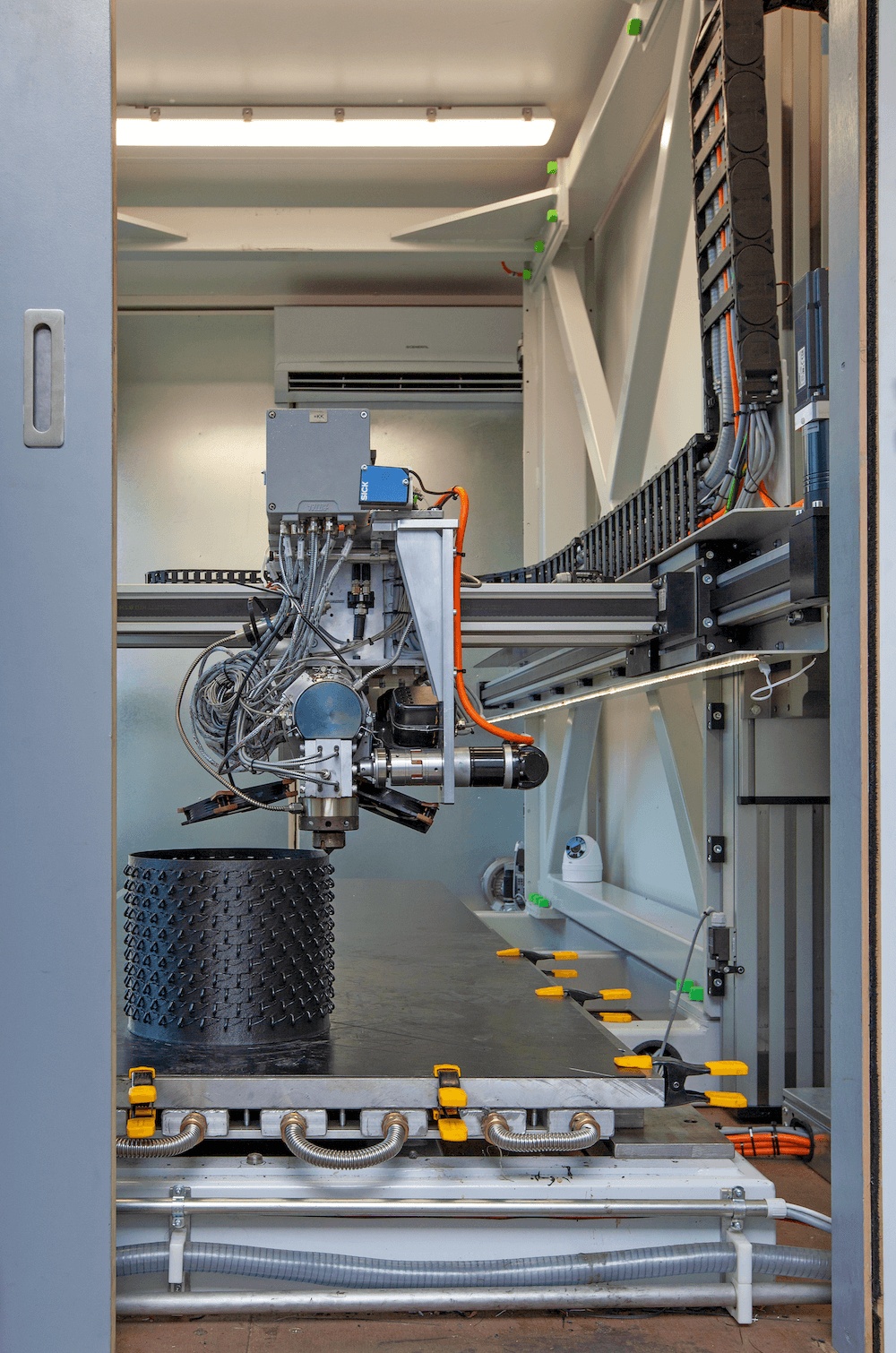

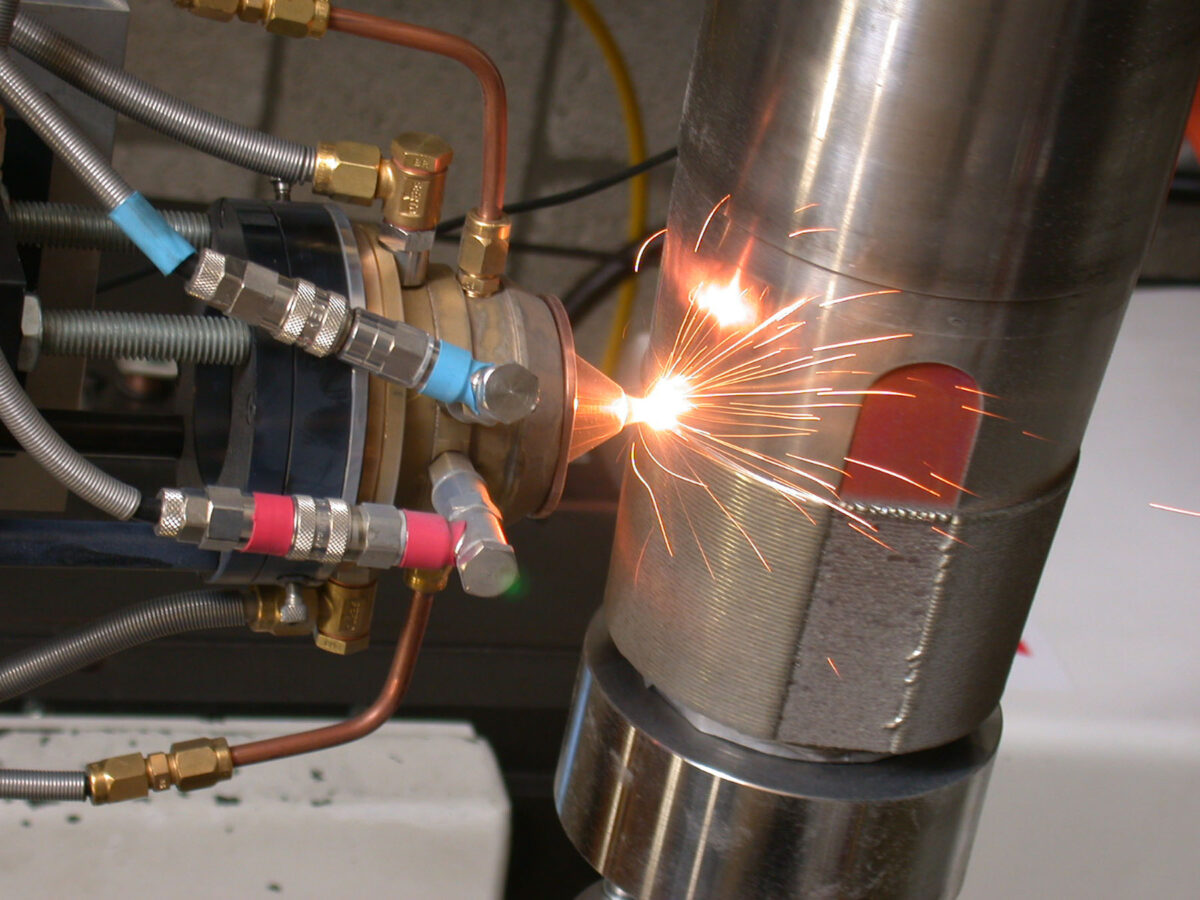

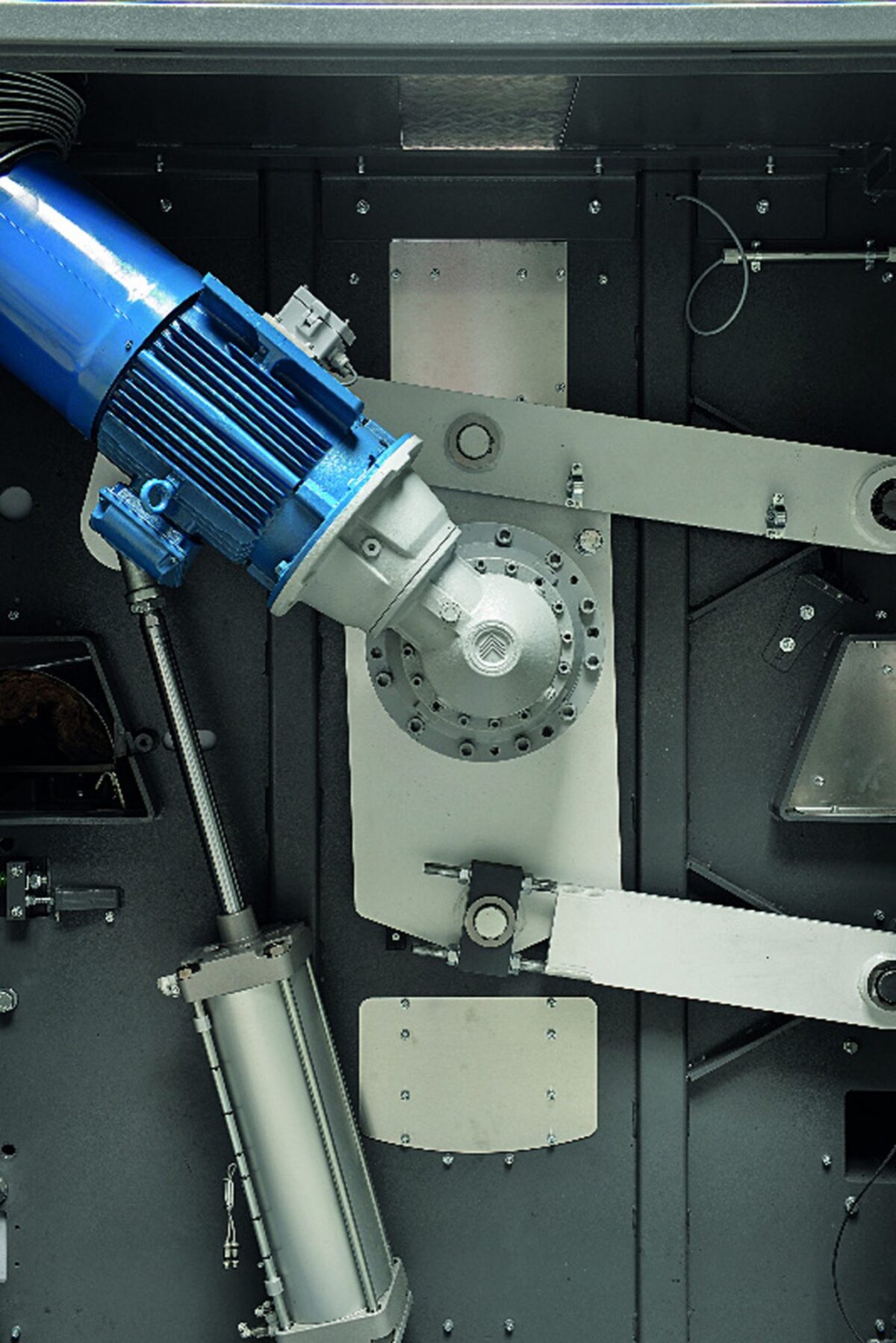

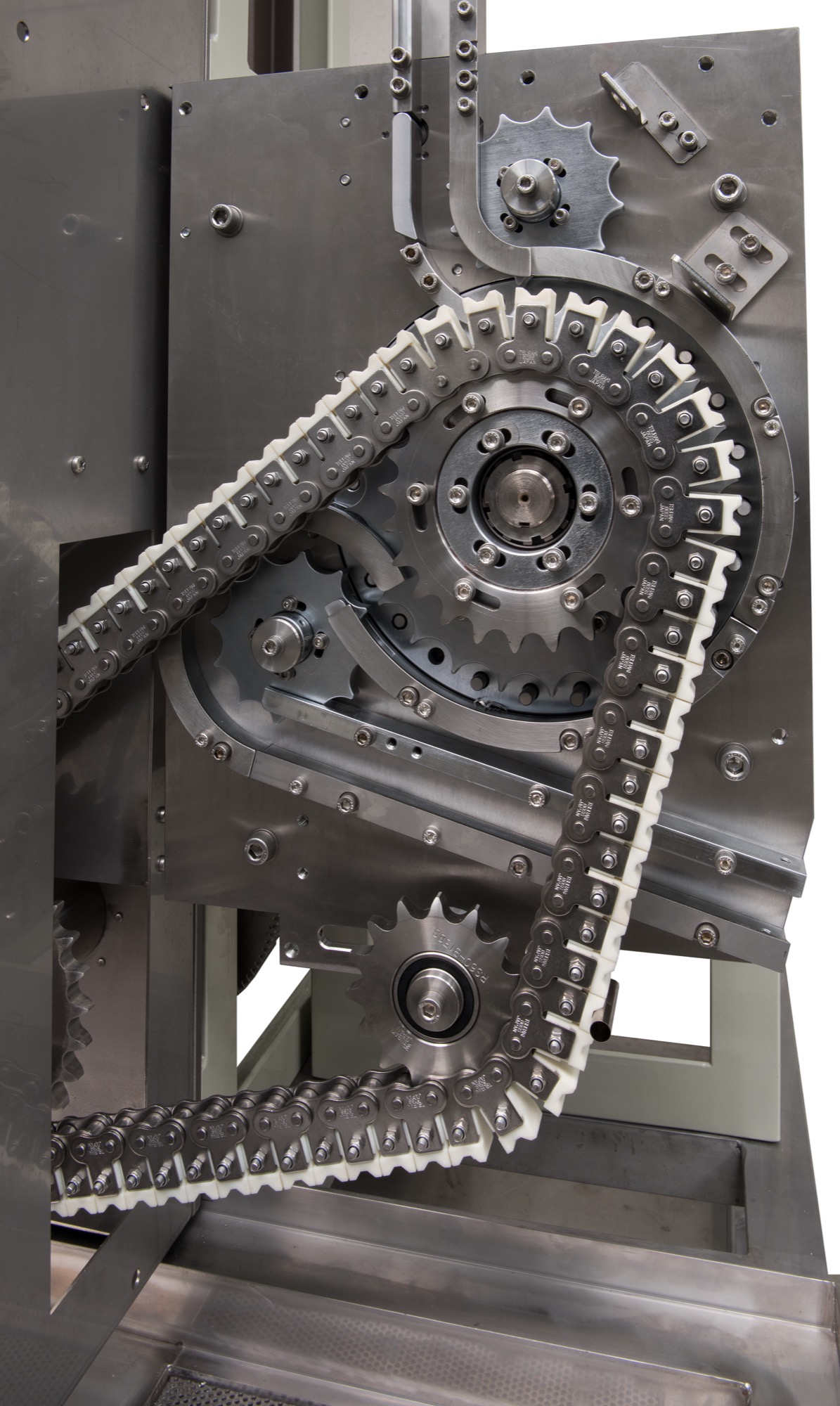

Manufacture

From design to assembly. We keep every step of building your machine in-house. So you get a finish of the highest quality.

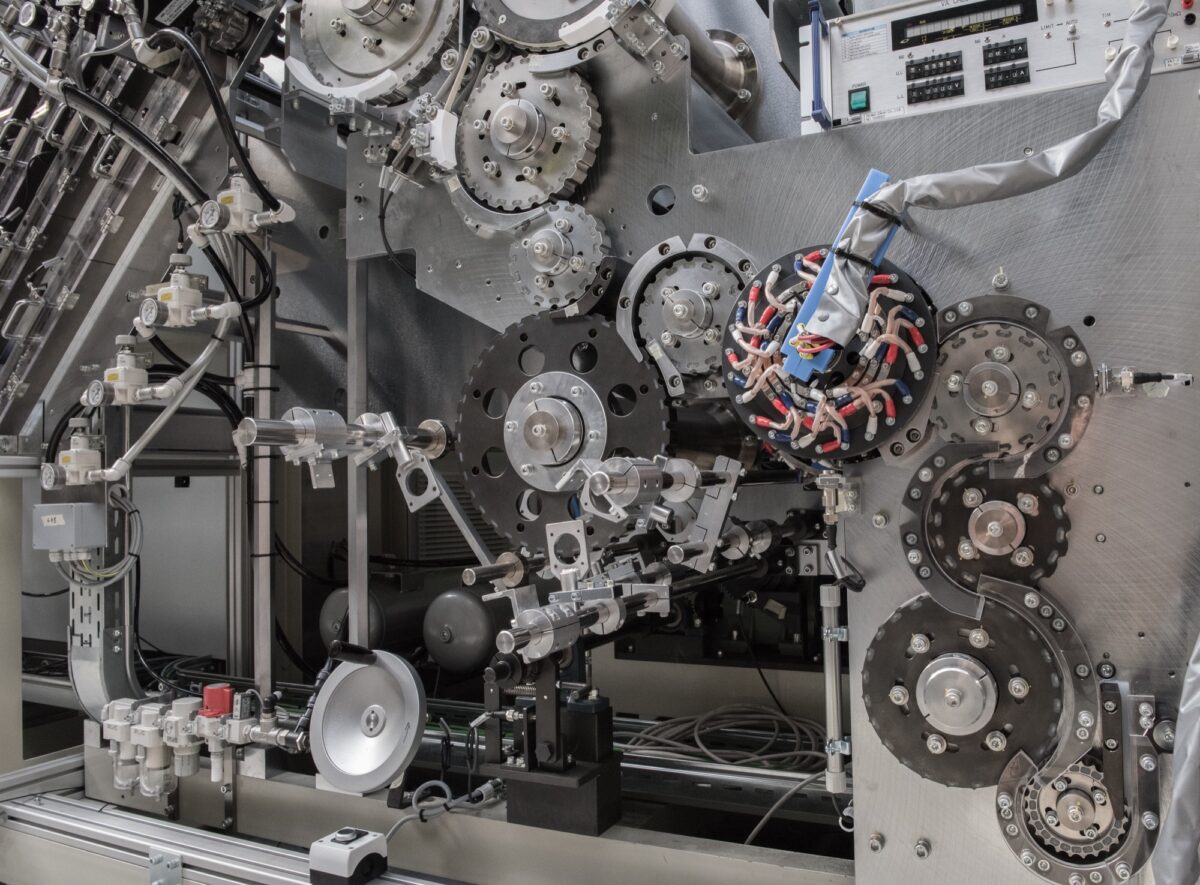

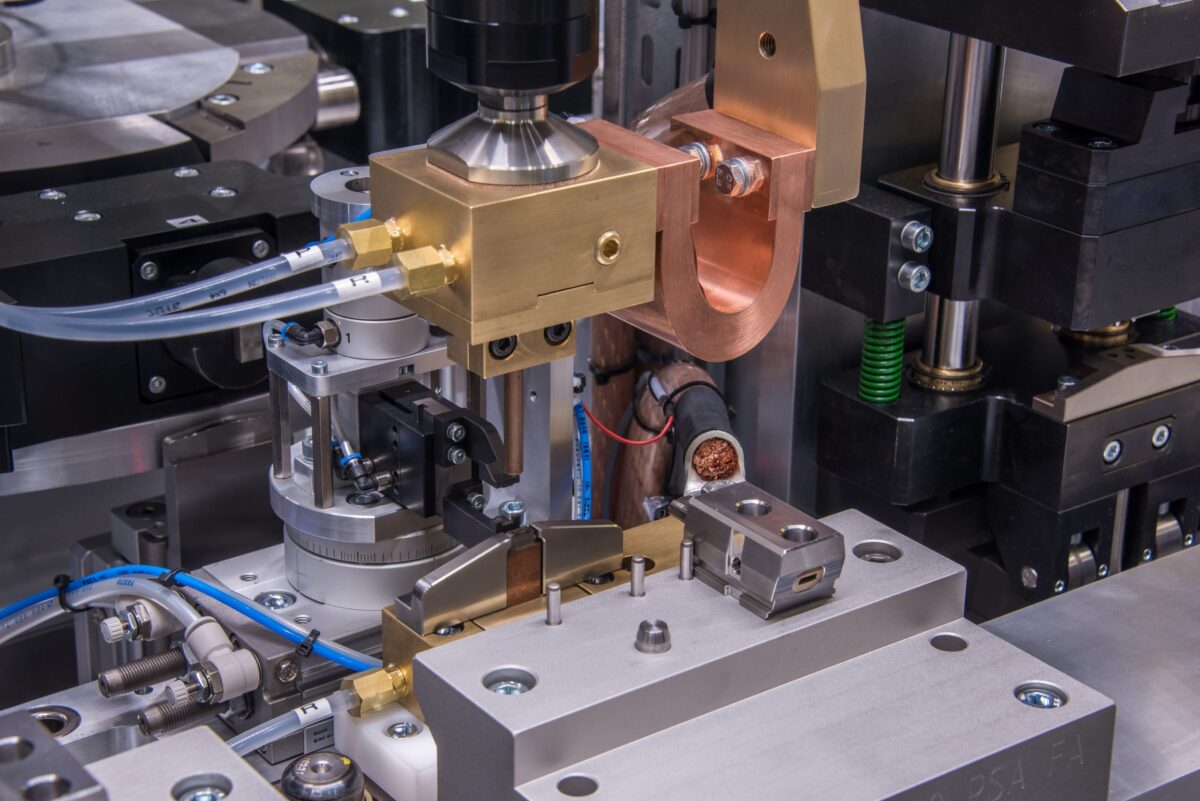

Retrofit

Conversion. Is your machine still mechanically sound? Or do you want to incorporate an innovation in an existing installation? We help you take several steps forward: software-wise and mechanically, electrically and digitally.

Whitepaper: machine upgrading