LINEAR SERVO TECHNOLOGY FOR A HIGHLY PRECISE INSPECTION MACHINE

Challenge

This automotive company wanted to check the quality of one of its critical components. To extreme precision.

The product consists of multiple zones, with specific tolerances for compressive strength for each zone. These tolerances also differ between models.

It is up to us to develop a new inspection machine that maps out the compressive strengths per zone extremely accurately.

Solution

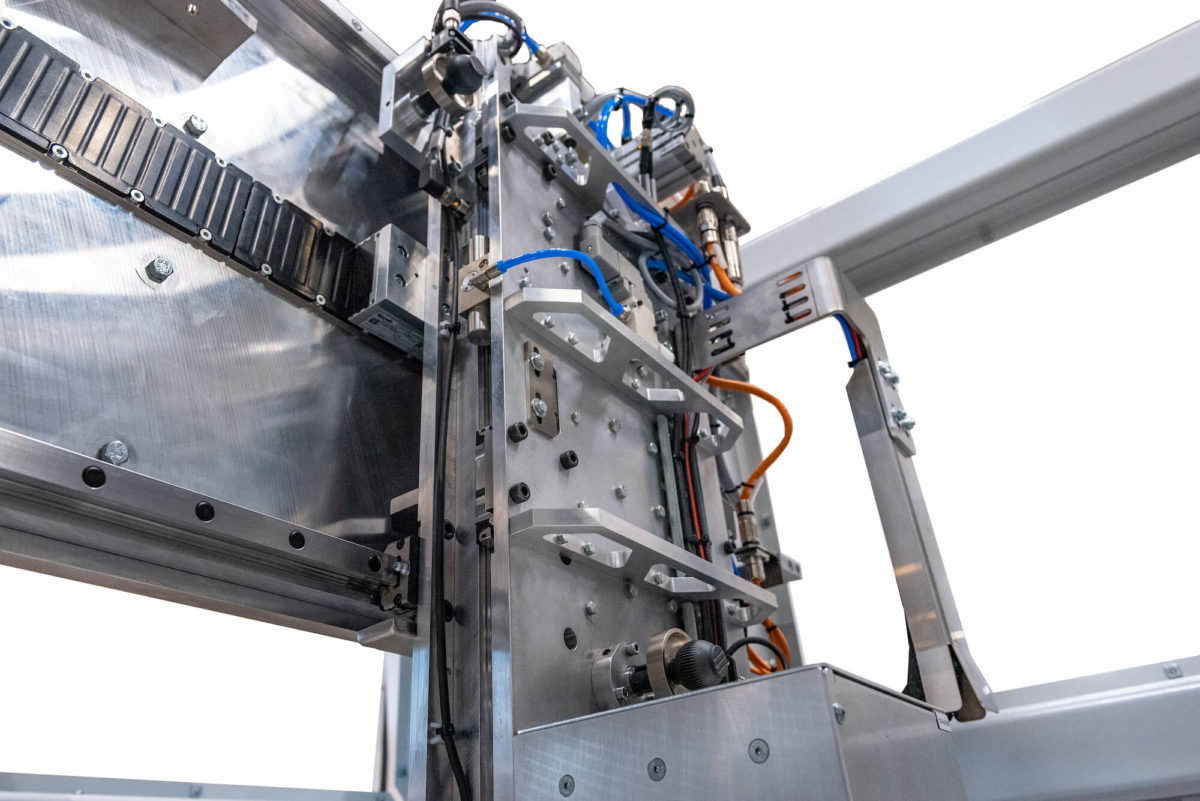

An inspection machine with a robot arm and a multi-point measuring system.

The robot arm presses each product against the measuring bar at a pressure and speed predetermined for each range. The built-in sensors record the pressure measurement per zone. This lets the operator check whether the product as a whole meets the requirements.

Because the measurement must be extremely precise, we opted for linear servo technology.

The alternatives for positioning the product on the measuring bar were a guide or a toothed belt. Or a sled and a toothed rack. But linear servo technology allows much more precise positioning, without sacrificing speed.

Results

A custom-developed and custom-built inspection machine. With the most advanced measuring technologies. And thus 100% certainty about the quality of this critical component.