AUTOMATIC INLINE THICKNESS MEASUREMENT OF BOARDS

Challenge

Within the Beaulieu International Group, the BerryAlloc® division offers a wide range of interior solutions for residential and commercial projects, from laminate, vinyl and parquet floors to wall panels.

Given the highly competitive global context, the strategic focus in the coming years will be to make maximum efforts on quality and process improvement. To distinguish it from its competitors, especially the Asian ones.

One of the crucial factors in making this a reality is extensive digitisation in the production environment. Maximizing the intelligent capture and processing of data leads to very detailed insights into the process, allowing rapid response without human intervention. To improve the results.

For their new extrusion line for boards at their production site in Wielsbeke, Berry Alloc wanted to roll out an installation for the automatic inline thickness measurement of the product. Accurate to within 0.01 millimetres.

These highly accurate inline measurements are then passed on to the higher-level MES system. In this way, Berry Alloc gets the information needed to automatically adjust the process settings.

An additional challenge is the variation in

- Colour

- Profile

- And temperature

Solution

Based on various tests and experiences, we chose a thickness measurement based on differential distance. This is done by moving distance sensors above and below the boards.

Given the desire to have 200 measuring points per plate, we opted for a dual-sensor implementation. This consists of 2 x 2 sets of sensors above and below mechanically linked to each other.

The servo drive passes the measuring positions to the system very accurately.

One of the challenges in choosing the sensors was the characteristic structure of these plates. Better known as ‘embossing’:

The accuracy of laser-based distance-measuring sensors increases with the thinness of the beam. Typically, a sensor like this will detect the hills and valleys in a plate with surface structure. Which leads to a false measurement.

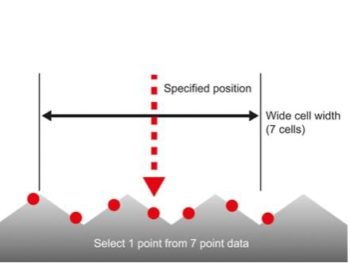

Our solution is to average different measurements to value that smooths out the peaks and valleys in the spot. So that the inline thickness measurement provides the required accuracy.

Results

A tailor-made measuring machine, with the most modern measuring techniques for inline thickness measurement that provides Berry Alloc with accurate data for realising their digital strategy. So that they can distinguish between quality and process optimisation.