Construction Industry

Challenge

Mosa is a Dutch tile manufacturer with more than 130 years of experience on the counter.

As a manufacturer of tile concepts for walls, floors, facades and terraces, Mosa attaches great importance to product quality and aesthetics.

In addition, attention to innovation and design are important values for Mosa.

Thanks to this innovative ability, Mosa is able to respond to specific customer requirements and supply small series.

VINTIV was commissioned to build a machine to prepare the production of a tile. Extra attention had to be paid to flexible and profitable production without sacrificing machine safety.

Solution

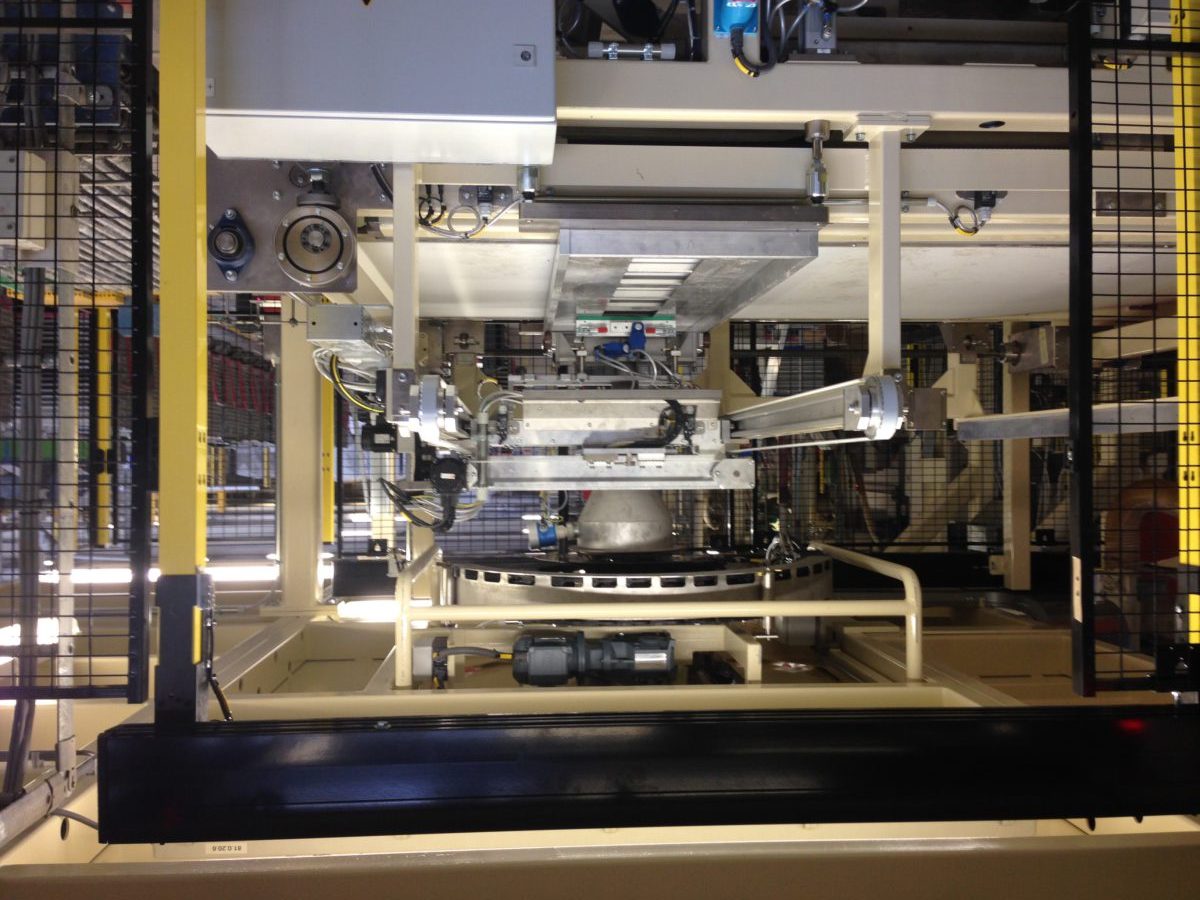

VINTIV has developed a machine that creates the top layer of a tile from raw materials and then places them on the bottom layer of the tile in the press.

The installation covers several floors and consists of several substations:

- Top layer raw material silos and conveyor belts

- Top layer stock bunkers

- Top layer milling and dosing stations

- Transport systems

- Funnel control unit

- Filling container and dosing unit

- Top layer slider

- Discharge transport

- Discharge system

Operators are safely protected from the dangers by various collective risk reductions.

Results

The manufacturing of tiles is so demanding and specific that commercially available standard machines simply do not comply.

By investing in this unique production machine, Mosa disposes of a custom-made installation that, in addition to a high return, also offers the necessary flexibility.

By using modern techniques, the output of this installation has greatly increased.