Giant 3D Printer

Challenge

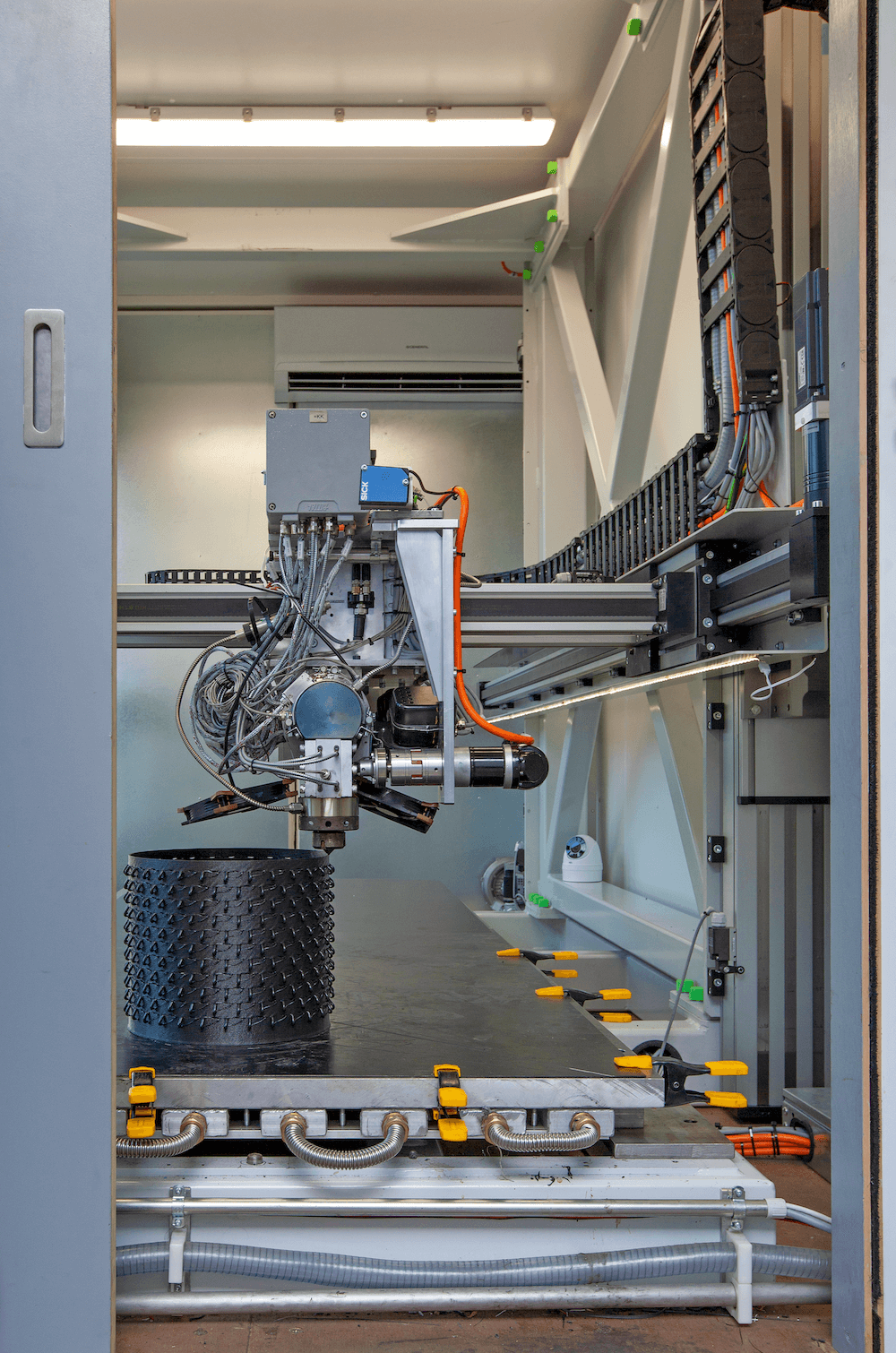

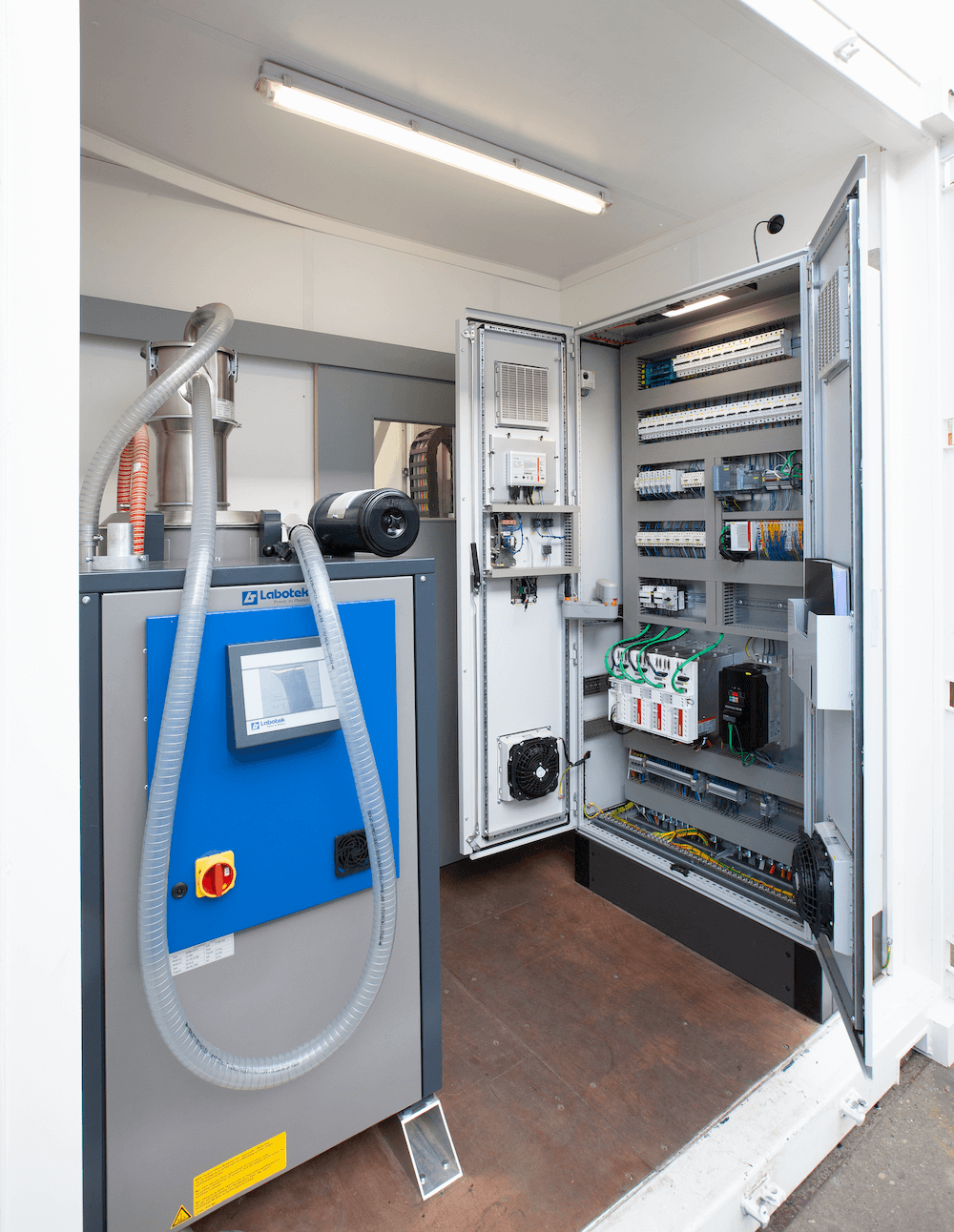

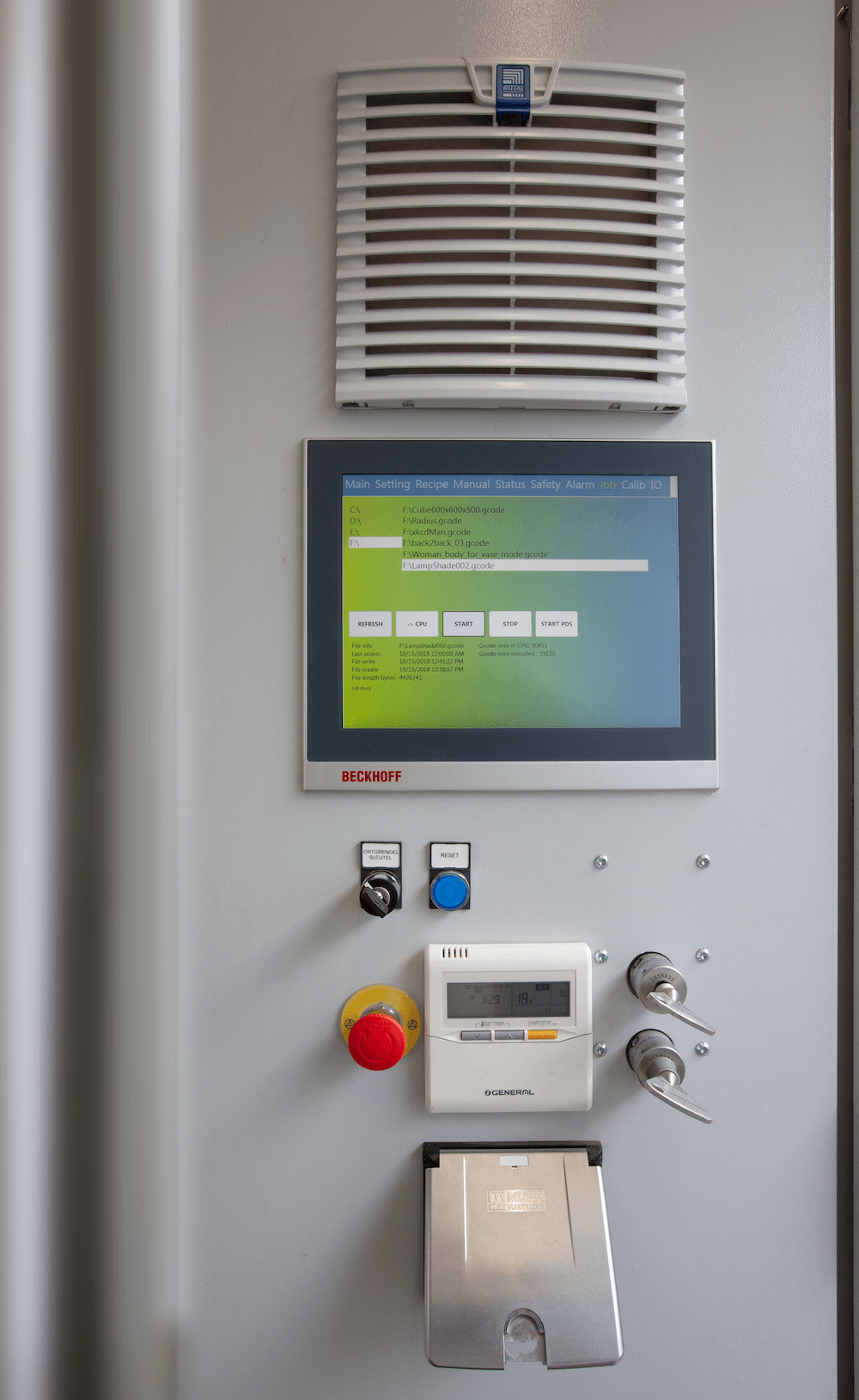

A giant 3D printer that transforms plastic waste into furniture. And which is also mobile. Start-up Colossus searched the market, but suppliers of 3D printers had nothing of that size. Either the existing technology proved too slow or far too expensive. So Colossus decided to build the printer itself. Or rather: to have it built. And that’s how we came into the picture.

Solution

Colossus has experience in extrusion and printing processes.

We have our knowledge of machine develoment, linear motion systems and safety functions, the actual construction process and software programming.

Based on this knowledge, we first gave Colossus a clear understanding of the feasibility, budget and timing of their future 3D printer. So that they had all the facts and figures to convince investors. In addition to our role as a machine builder, we advised them on their business plan and put them in contact with the right people in our network.

Results

A working prototype of the world’s largest mobile 3D printer. The first make served as the basis for a total serie of 3 printers.