IRONING INSTALLATION

Challenge

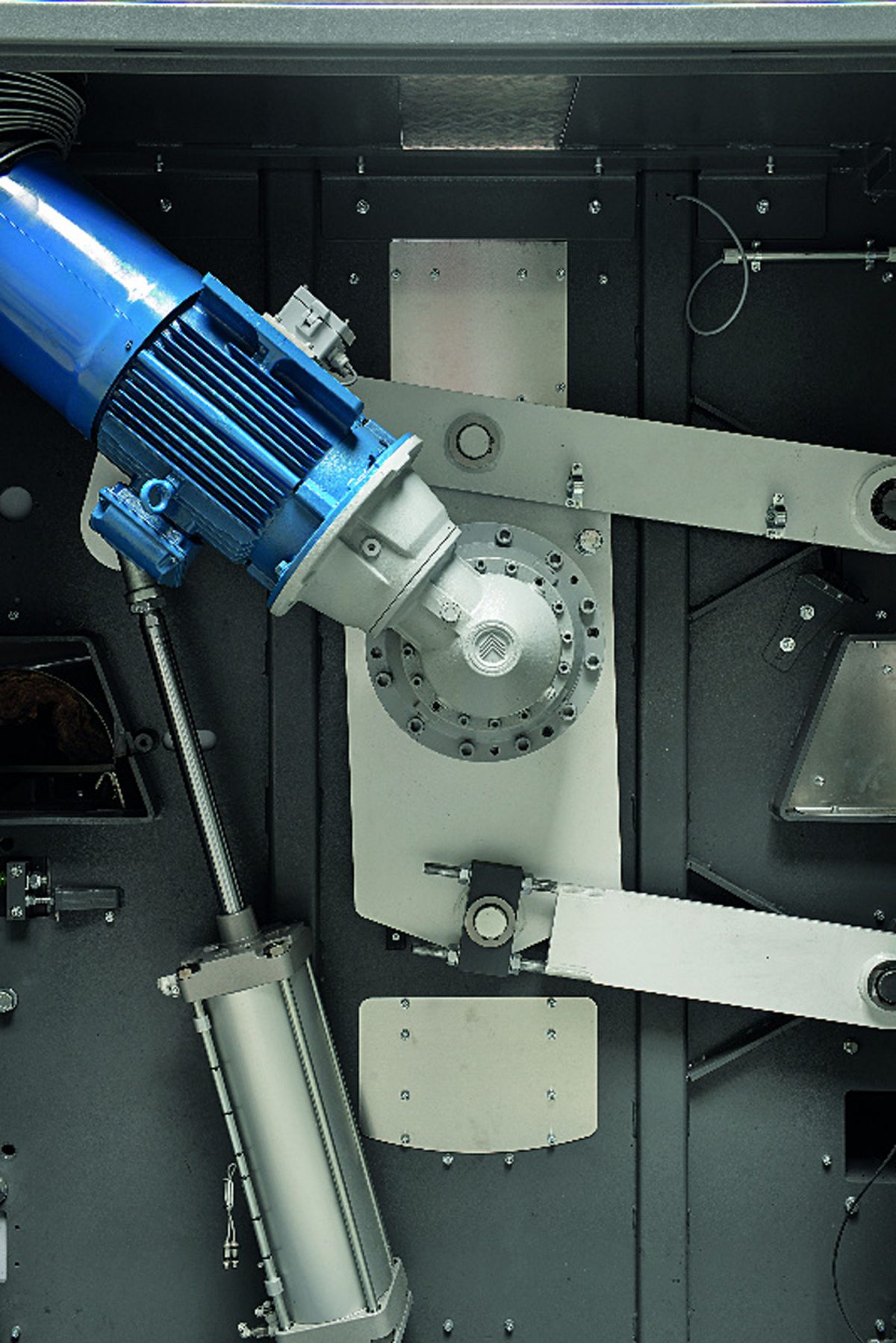

A highly technological ironing installation weighing 13,000 kilograms. That is the impressive result of our collaboration with Texfinity. Texfinity focuses on the automation of processes in industrial laundries. We took care of the engineering and assembly of an industrial ironing machine.

Our assignment: build an industrial ironing installation. But that is more than multiplying the dimensions of a ‘normal’ flatiron. The technology goes further. Much further. Everything is fully computer-controlled.

Solution

We developed and built a first prototype for Texfinity. This installation was extensively tested in a laundry in Antwerp. Where you can still admire it at laundry Gomoli in Ekeren.

In the next phase we not only took care of the complete mechanical and electrical development, our automation department also wrote the custom software and user interface. The assembly of this industrial wringer was done here in our workshops. A great challenge for our boys, given its dimensions of five metres by four. And a height of three metres… and a weight of thirteen tonnes.

Results

The end user gets a smart machine with the necessary technical ingenuity. But it is also a machine that consumes less energy than all the other installations on the market. This is thanks to the special and controlled flow of the thermal oil, and a very efficient air evacuation system.