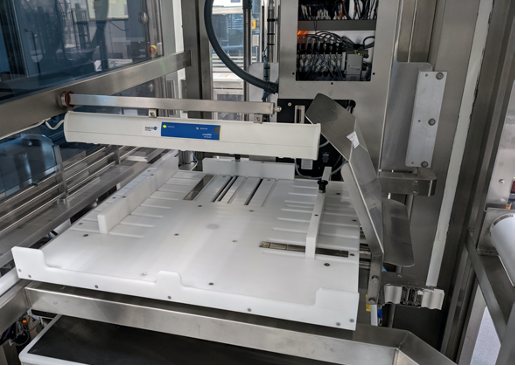

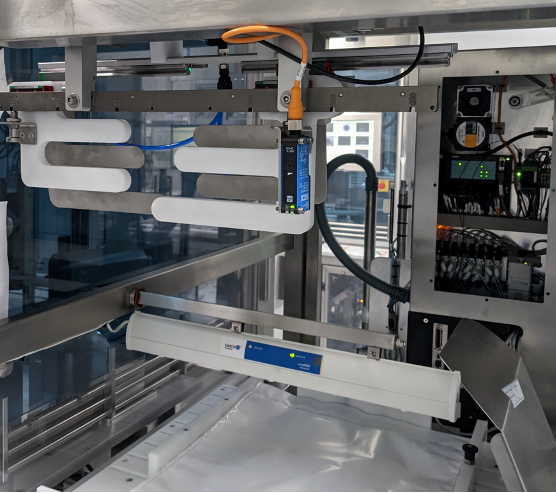

RETROFITTING PACKAGING MACHINERY AT A HEALTHCARE COMPANY

Challenge

This healthcare company has a number of similar and older packaging machines. Thanks to good maintenance, these machines have always worked well.

As a global player, the company must meet very high standards for quality, reliability and contamination avoidance. To meet the increasingly important demands of authorities and customers, they decided to thoroughly assess their packaging machines and formulate improvements.

The fact that these are highly multifunctional machines – both in terms of packaging and type and quantity of content – made this assignment particularly complex.

In addition to even higher reliability and accuracy, the costs obviously play a role in the retrofit of these packaging machines.

Solution

Our in-depth cost-benefit analysis showed that a retrofit was clearly better than buying new machines. Although the functionality of the packaging machines does not change in terms of content, the retrofit offers an efficient, cutting-edge solution. With a shorter lead time than required for the design and construction of a new machine.

This retrofit brings the packaging machines to an ‘as new’ condition. It significantly increases the value and expected service life of the machine. In addition to mechanical improvements, we also brought the operating system to the current technological level.

Results

This retrofit protects the company from sudden unexpected outages and operational errors. And all this for a sound, well-considered investment and a shorter lead time than that needed for a new machine.